Giving smart materials an IQ test at SSRL

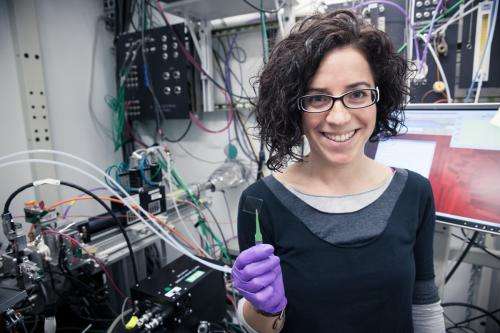

Anna Llordés, a chemist at Lawrence Berkeley National Laboratory's Molecular Foundry, looks for simple, inexpensive ways to make "smart" materials that save or store energy. One way she and her colleagues do this is by combining metal oxides that have desirable properties.

What they don't know is how these materials will act in combination: Will the resulting composite retain the desirable structures and properties of its individual ingredients? Will the ingredients influence each other – for good or ill? And how can she tell what's really going on?

That's where Beam Line 11-3 at SLAC's Stanford Synchrotron Radiation Lightsource (SSRL) comes in.

"11-3 is a really important beamline for us when we're developing a new material," Llordés said. "It allows a quick but detailed evaluation of the crystalline structure of thin films."

Take, for example, one of their latest discoveries: a new type of transparent smart film that can be applied to a pane of window glass to control the amount of sunlight or heat that enters a room, thereby cutting electricity costs. These films have "electrochromic" properties, meaning the amount of sunlight they let through can be changed by applying a voltage. The ability to selectively filter different wavelengths of light is a new – and hard-won – development in what's called "smart window" technology.

Llordés and her co-workers created this particular film by combining nanocrystals of tin-doped indium oxide (ITO), which absorbs infrared energy, with niobium oxide glass, which screens visible light.

What was surprising, she said, was the synergy between the two materials. "When the ITO nanocrystals bond to the glassy niobium oxide, you get better properties that you'd expect," she said. In particular, the niobium oxide is much improved as a window coating – it's five times better at blocking light than niobium oxide without nanocrystals. In addition, the composite material stands up better to repeated on-off cycles.

But why the big improvement? And what nanocrystal-in-glass recipe resulted in the best film?

To find out, Llordés used a technique called grazing incidence X-ray diffraction at Beam Line 11-3 to study the structures of films that had been processed at temperatures ranging from 400°C to 650°C. She discovered that the film with the best qualities forms between 400°C and 500°C.

She also discovered the film is a glassy matrix that actually incorporates the ITO nanocrystals into its structure, instead of simply trapping them as impurities. The glass molecules bond with the nanocrystals, changing the structure of the glass and affecting its properties. It's this bond that makes the whole of the film so dramatically better than the sum of its parts.

"The work on 11-3 helped us prove we had a very unique composite material," Llordés said, and during her most recent trip to the beamline, she investigated materials that are even easier and more energy-efficient to produce.

Finding new, useful materials that are energy-efficient to produce is her driving interest, said Llordés, Beamline 11-3 helps her do that.

But SSRL has another meaning for the native Spaniard, as well.

"When I first came here three years ago, the people at SSRL were very helpful and welcoming," she said. "They explained how to run the experiments, and they were always open, fun and ready to talk science.

"I'm always happy when I need to come to SSRL."

Provided by SLAC National Accelerator Laboratory