Pressure cooking to improve electric car batteries

Batteries that power electric cars have problems. They take a long time to charge. The charge doesn't hold long enough to drive long distances. They don't allow drivers to quickly accelerate. They are big and bulky.

Researchers at the University of California, Riverside's Bourns College of Engineering have redesigned the component materials of the battery in an environmentally friendly way to solve some of these problems. By creating nanoparticles with a controlled shape, they believe smaller, more powerful and energy efficient batteries can be built.

"This is a critical, fundamental step in improving the efficiency of these batteries," said David Kisailus, an associate professor of chemical and environmental engineering and lead researcher on the project.

In addition to electric cars, the redesigned batteries could be used for municipal energy storage, including energy generated by the sun and wind.

The initial findings are outlined in a just published paper called "Solvothermal Synthesis, Development and Performance of LiFePO4 Nanostructures" in the journal Crystal Growth & Design.

Kisailus, who is also the Winston Chung Endowed Professor in Energy Innovation, and Jianxin Zhu, a Ph.D. student working with Kisailus, were the lead authors of the paper. Other authors were: Joseph Fiore, Dongsheng Li, Nichola Kinsinger and Qianqian Wang, all of whom formerly worked with Kisailus; Elaine DiMasi, of Brookhaven National Laboratory; and Juchen Guo, an assistant professor of chemical and environmental engineering at UC Riverside.

The researchers in Kisailus' Biomimetics and Nanostructured Materials Lab set out to improve the efficiency of Lithium-ion batteries by targeting one of the material components of the battery, the cathode.

Lithium iron phosphate (LiFePO4), one type of cathode, has been used in electric vehicles because of its low cost, low toxicity and thermal and chemical stability. However, its commercial potential is limited because it has poor electronic conductivity and lithium ions are not very mobile within it.

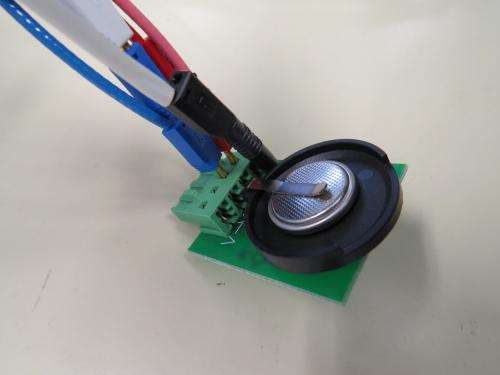

Several synthetic methods have been utilized to overcome these deficiencies by controlling particle growth. Here, Kisailus and his team used a solvothermal synthetic method, essentially placing reactants into a container and heating them up under pressure, like a pressure cooker.

Kisailus, Zhu and their team used a mixture of solvents to control the size, shape and crystallinity of the particles and then carefully monitored how the lithium iron phosphate was formed. By doing this, they were able to determine the relationship between the nanostructures they formed and their performance in batteries.

By controlling the size of nanocrystals, which were typically 5,000 times smaller than the thickness of a human hair, within shape-controlled particles of LiFePO4, Kisailus' team has shown that batteries with more power on demand may be generated.

These size and shape modulated particles offer a higher fraction of insertion points and reduced pathlengths for Li-ion transport, thus improving battery rates. Kisailus and his team are currently refining this process to not only further improve performance and reduce cost, but also implement scalability.

More information: pubs.acs.org/doi/abs/10.1021/cg4013312

Provided by University of California - Riverside