Study finds natural compound can be used for 3-D printing of medical implants

(Phys.org) —Researchers from North Carolina State University, the University of North Carolina at Chapel Hill and Laser Zentrum Hannover have discovered that a naturally-occurring compound can be incorporated into three-dimensional (3-D) printing processes to create medical implants out of non-toxic polymers. The compound is riboflavin, which is better known as vitamin B2.

"This opens the door to a much wider range of biocompatible implant materials, which can be used to develop customized implant designs using 3-D printing technology," says Dr. Roger Narayan, senior author of a paper describing the work and a professor in the joint biomedical engineering department at NC State and UNC-Chapel Hill.

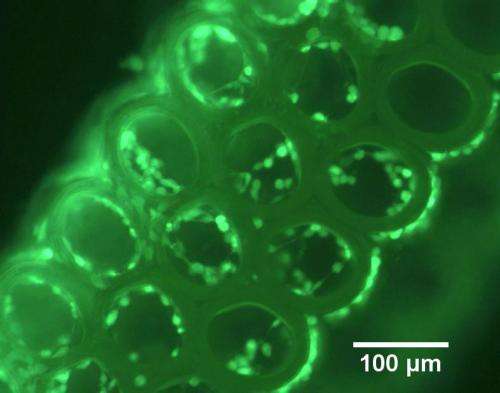

The researchers in this study focused on a 3-D printing technique called two-photon polymerization, because this technique can be used to create small objects with detailed features – such as scaffolds for tissue engineering, microneedles or other implantable drug-delivery devices.

Two-photon polymerization is a 3-D printing technique for making small-scale solid structures from many types of photoreactive liquid precursors. The liquid precursors contain chemicals that react to light, turning the liquid into a solid polymer. By exposing the liquid precursor to targeted amounts of light, the technique allows users to "print" 3-D objects.

Two-photon polymerization has its drawbacks, however. Most chemicals mixed into the precursors to make them photoreactive are also toxic, which could be problematic if the structures are used in a medical implant or are in direct contact with the body.

But now researchers have determined that riboflavin can be mixed with a precursor material to make it photoreactive. And riboflavin is both nontoxic and biocompatible – it's a vitamin found in everything from asparagus to cottage cheese.

More information: The paper, "Two-photon polymerization of polyethylene glycol diacrylate scaffolds with riboflavin and triethanolamine used as a water-soluble photoiniator," is published online in Regenerative Medicine. www.futuremedicine.com/doi/full/10.2217/rme.13.60

Abstract

Aim: In this study, the suitability of a mixture containing riboflavin (vitamin B2) and triethanolamine (TEOHA) as a novel biocompatible photoinitiator for two-photon polymerization (2PP) processing was investigated. Materials & methods: Polyethylene glycol diacrylate was crosslinked using Irgacure® 369, Irgacure 2959 or a riboflavin–TEOHA mixture; biocompatibility of the photopolymer extract solutions was subsequently assessed via endothelial cell proliferation assay, endothelial cell viability assay and single-cell gel electrophoresis (comet) assay. Use of a riboflavin–TEOHA mixture as a photoinitiator for 2PP processing of a tissue engineering scaffold and subsequent seeding of this scaffold with GM-7373 bovine aortic endothelial cells was also demonstrated. Results: The riboflavin–TEOHA mixture was found to produce much more biocompatible scaffolds than those produced with Irgacure 369 or Irgacure 2959. Conclusion: The results suggest that riboflavin is a promising component of photoinitiators for 2PP fabrication of tissue engineering scaffolds and other medically relevant structures (e.g., biomicroelectromechanical systems).

Provided by North Carolina State University