Innovative concept for knee cartilage treatment

Researchers have developed a material that can be used for the controlled release of a substance when subjected to cyclic mechanical loading. This work, carried out within the context of the National Research Programme "Smart Materials" (NRP 62), offers a potential treatment method for specific tissues such as knee cartilage.

In order to regenerate, knee cartilage, paradoxically, needs to be placed under mechanical stress, as happens whenever we take a step and our knees take our weight. When stimulated in this way, the cartilage cells develop receptors that are sensitive to the growth factors produced by the organism. It is also at this very moment that they would be most receptive to medication. Working on this basis, Dominique Pioletti and Harm-Anton Klok from EPF Lausanne have developed a smart material that only releases a substance when the material is mechanically loaded.

Threshold effect

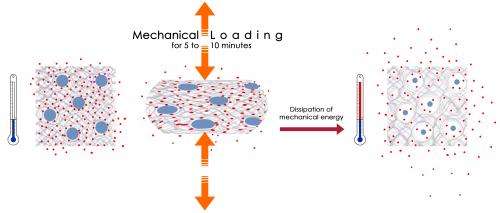

As they describe in a recent publication, their material takes the form of a hydrogel matrix, liposome-type nanoparticles and, finally, a payload – in this case a dye. When subjected to cyclic mechanical loading, the hydrogel matrix heats up. Once subjected to heat, the diameter of the liposomes shrinks significantly. This frees up space in the matrix, increasing its permeability and facilitating the release of the dye from the matrix. "One of the main difficulties has been the development of nanoparticles that respond to our specification," explains Dominique Pioletti. "Basically, for the concept to work, their response to the heating process must have a very clear threshold between the two to three degrees that separate the static and stimulated states."

The researchers then wanted to verify that it was actually the heating process resulting from the repetition of the mechanical loading that caused the dye to be released. During an initial experiment, the material was subjected to cyclic mechanical loading but the heat produced was evacuated in order to prevent any local temperature increase in the material. "This test enabled us to exclude a sponge-type function, whereby the dye was only being released as a result of the pressure," explains Dominique Pioletti. During a second experiment, the nanoparticles were removed. The matrix heated up as expected due to the cyclic mechanical loading but none of the dye was released. The researchers concluded that the three elements of the composite material were required for the system as a whole to function as intended.

Long-term prospects

Whilst the researchers have been able to demonstrate the validity of their concept, Dominique Pioletti stresses that a future treatment is still a long way off. "First of all we need to develop a hydrogel and nanoparticles that are safe and biodegradable, before progressing to clinical trials. And, above all, we need to find partners interested in investing in our project."

More information: Moghadam, M. et al. (2013) Controlled release from a mechanically-stimulated thermosensitive self-heating composite hydrogel, Biomaterials. DOI: 10.1016/j.biomaterials.2013.09.065

Journal information: Biomaterials

Provided by Swiss National Science Foundation