February 27, 2013 report

Architect unveils concept of 4D printing at TED conference (w/ video)

(Phys.org)—Skylar Tibbits, architect, artist, computer scientist and director of MIT's Self-Assembly Lab has given a talk at the recent TED conference describing what is being called 4D printing. The new technology, as he explained, involves printing 3D objects that change after they've been printed—a self assembly process whereby printed material forms itself into another shape after being subjected to an energy source, e.g. heat, electricity, light, sound, or as he showcased in his demonstration, submersion in water.

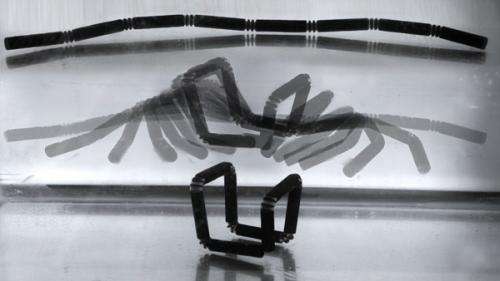

The whole idea is to start with materials that react in predictable ways to energy sources. To that end, Tibbits has been working with a company based in Minneapolis called Stratasys—they make 3D printers and recently acquired an Israel materials development company called Objet. The new union has resulted in a collaboration that has led to the development of a material that changes shape in "programmable" ways when submersed in water. To program the material, Tibbits has also been working with AutoDesk. The result is a 3D printable material that when dunked into a tank of water, changes itself into a recognizable shape. A single strand for example, suddenly comes to life and forms the word "MIT" in two dimensions, another pulls itself into an open ended three dimensional cube. This seemingly magical act comes about by programming different parts of the material to respond as desired. A strand for example, is actually composed of a series of stiff chunks connected together by rubberlike material that can bend. To cause an object to shape itself then, means causing the chunks to bend relative to one another at prescribed angles.

It's all part of a whole new science Tibbits said, one that may very well revolutionize the way things are made. Consider materials that can be printed and sent to harsh environments for self-construction—underwater labs, for example, or research stations in space. Just add light, water or heat, and such structures form themselves into whatever has been preprogrammed from the safety of an ordinary office building. Tibbits describes it as similar to embedding smarts in a material—a way to extend the printing window to after the printer has done its work to allow for self-assembly of three dimensional objects that are limited only by our imaginations.

More information: www.sjet.us/MIT_4D%20PRINTING.html

© 2013 Phys.org