Microfabrication methods to help navigate a day without GPS

Military missions of all types need extremely accurate navigation techniques to keep people and equipment on target. That is why the Military relies on GPS or, when GPS is unavailable, precise sensors for navigation. These sensors, such as gyroscopes that measure orientation, are bulky and expensive to fabricate. For example, a single gyroscope designed as an inertial sensor accurate enough for a precision missile can take up to 1 month to be hand assembled and cost up to $1 million. DARPA has made progress in developing less expensive fabrication methods for inertial sensors and is making them orders of magnitude smaller and less expensive.

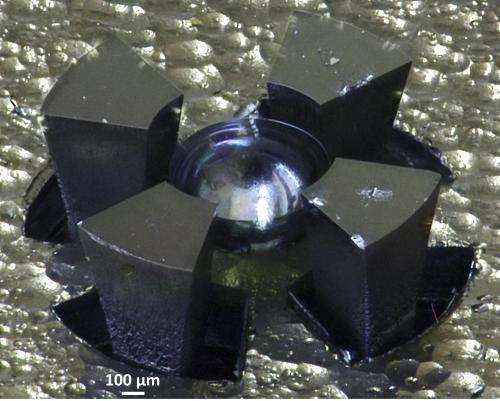

DARPA is developing new fabrication techniques for microscale inertial sensors with the goal of creating enough accuracy to replace the large, expensive gyroscopes used today. This work is being done under the Microscale Rate Integrating Gyroscope (MRIG) effort of the Micro-Technology for Positioning, Navigation and Timing (Micro-PNT) program. During the recently completed first phase, MRIG focused on 3-D microfabrication methods using nontraditional materials, such as bulk metallic glasses, diamond and ultra-low expansion glass. Small 3-D structures such as toroids, hemispheres and wineglass-shaped structures were successfully fabricated, shifting away from the 2-D paradigm of current state-of-the-art microgyroscopes.

These microscale inertial sensors work like Foucault pendulums commonly found in museums. The swinging direction of the pendulum slowly changes as the Earth rotates. Instead of a swinging pendulum, microscale inertial sensors send out vibrations across the surface of a 3-D structure. The precession of the standing wave is measured and any changes reflect a change in orientation.

Among the several new fabrication methods created by DARPA to work with these microscale inertial sensors are:

Glass-blowing. Researchers developed fabrication methods that replicate traditional glass-blowing techniques at the microscale. The result is tiny 3-D wineglass-shaped inertial sensors. These sensors are symmetrical enough to have a frequency split approaching 10 hertz—a result never before achieved at this size and approaching levels of symmetry required for high-quality navigation devices.The frequency split is a measure to predict the symmetry—and thus accuracy—of the device. It is a measure of the difference between two different axes of elasticity. The greater the difference, the more imperfection is present, resulting in a less accurate sensor.

Blown quartz. Similar to glass blowing, quartz blowing can be used to make an even more symmetric structure. Researchers developed fabrication techniques needed to heat quartz to 1,700 degrees Celsius (a typical softening point for glass is about 800 degrees Celsius) and to then cool it rapidly. The fabrication can be performed in large quantity batches, producing hundreds of devices on a single wafer.

Atomic layering of diamond. Layering diamond over a blown structure or depositing CVD diamond in a micro-well on the substrate have been shown to be effective, promising methods for creating highly symmetric, accurate 3-D inertial-sensor structures.

"These new fabrication methods were thought to be unrealistic just a few years ago," said Andrei Shkel, the DARPA program manager. "The first phase of MRIG has proven these new fabrication techniques and begun the process of validating the new structures and materials through testing. Phase 2 has kicked off, in which DARPA seeks to hone these methods to create and demonstrate operational devices."

Phase 2 performers seek to make these devices even more accurate and reliable by reducing frequency split from 10 Hz to 5 Hz, increasing decay times from 10 seconds to 100 seconds, and decreasing volume from 20 mm3 to 10 mm3. The final goal of Phase 2 is to demonstrate a working, first-of-its-kind microrate integrating gyroscope.

"As work continues, DARPA hopes these new technologies will enable large-scale production of navigation-grade microscale inertial sensors," added Shkel. "Production of 3-D inertial sensors with these new techniques would cost about the same as today's integrated circuit, making them orders of magnitude smaller, cheaper and more capable than current microgyroscopes."

Provided by DARPA