July 24, 2012 report

NASA researchers looking to take additive manufacturing into space

(Phys.org) -- Over the past several years, additive manufacturing has become the golden child of process engineering. This is because it allows parts to be made faster, more cheaply and in some cases to be made at all. Now space engineers are looking at additive processing technology as a means for allowing astronauts on extended missions to build their own replacement parts during their trek, rather than relying on carrying tons of spare parts with them.

Additive manufacturing refers to using techniques to add material to a beginning base of nothing to create something new as opposed to the way things have generally been done up to now, i.e. creating a big chunk of something and then removing the bits that are not wanted, generally by cutting and then machining. Besides the obvious reduction in material costs, there is also a reduction in machining costs if the part is made nearly perfect in the first step. Some additive processing technologies are referred to as 3D printing because the process is very similar to that used in inkjet printers. If an inkjet printer used thicker ink and repeatedly passed over a page, for example, eventually the ink would build up, producing a three dimensional object and that is what is at the heart of additive processing.

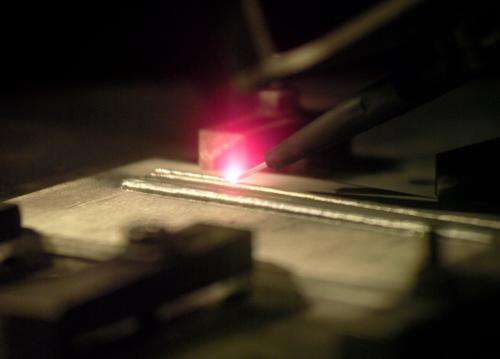

Engineers at NASA are currently testing something they call EBF3 for Electron Beam Freeform Fabrication, which marries inkjet technology with welding techniques. In this process, a wire is heated to the melting point using an electron beam, similar to when two pieces of metal are welded together. But instead of joining pieces, the EBF3 adds new layers of material building up three dimensional objects. The result is a process that produces no waste and that can be preconfigured and run in the same fashion as robots that weld parts together when making cars.

Because no one can predict which parts on a spacecraft might fail during a long trip, tons of spare parts would need to be carried along to ensure a safe and productive trip, unless most of those parts could be created on the fly by the astronauts themselves. That’s what the engineers working in several NASA facilities are working on right now. The trick is to build an additive processing machine that is small enough to take on a space flight mission, yet versatile enough to allow for adding materials of many different types while fashioning just one part, i.e. metal, plastic, rubber, etc. Thus far, engineers have tested additive technologies on planes that simulate zero gravity and have found their machines work just as well as when used here on Earth. The next step is to put together a program to test the machines by astronauts aboard the International Space Station.

More information: www.nasa.gov/multimedia/videog … ml?media_id=29574541

© 2012 Phys.org