NRL researchers develop improved non-skid coating for shipboard applications

Scientists in the Chemistry Division at the Naval Research Laboratory have developed a novel two-component siloxane-based non-skid coating for use on flight-decks and walk-ways of U.S. Navy ships. The new coating is more durable, color retentive, chemical resistant and cheaper due to a longer life expectancy than traditional epoxy-based coatings. This research is funded by the Office of Naval Research's (ONR's) Future Naval Capability Program (Dr. Airan Perez) and supported by Naval Sea Systems Command.

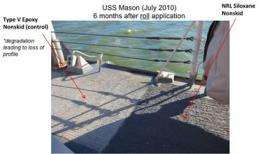

Mr. John Wegand, program team member, at NRL's Center for Corrosion Science and Engineering, explains "The new siloxane-based coating possesses greater external durability in harsh operational environments, improved traction capabilities, ease of application and most importantly, a longer life-span reducing the overall cost of the elements compared to the current epoxy and amine component coating. The new coating is quite versatile; it can be rolled or spray-applied over either a primed or bare-metal surface. We have noted extremely positive results from our recent demonstrations conducted on several Navy ships based in Norfolk, Virginia."

The Navy installs nearly 3.7 million square feet of non-skid coating per year at an annual cost of over $56 million. The maximum life expectancy of the present non-skid coating is just 18 months. These coatings are composed of aromatic epoxy resins, which although initially provide good hardness and chemical resistance, are notorious for degrading rapidly when exposed to the harsh external environmental conditions that the U.S. Navy routinely encounters at sea. The material is also difficult to apply because of its short pot life and slow drying time. Both of these attributes often lead to premature failure or damage to the coatings.

Demonstration results of the newly developed silicon based non-skid coating have shown it to be much stronger, durable, color retentive, chemical resistant and much more forgiving in the application process than the current coating. Its versatility allows for application by either spraying or rolling over either primed or directly to clean and blasted steel surfaces, because of its improved bonding capabilities. "Test results proved our new coating material greatly outperformed the current coating and met all research goals for this program, especially with regard to UV and chemical resistance," concluded Mr. Wegand

As the technical lead for ONR and NAVSEA, the NRL research team's main objective was to extend the service life of Navy non-skid systems. This includes identifying, developing and/or testing next-generation non-epoxy alternatives for extended durability flight and general deck performance, as well as addressing heat-resistant issues associated with current and future vertical launch aircraft requirements.

Provided by Naval Research Laboratory