June 4, 2012 feature

Friction almost vanishes in microscale graphite

(Phys.org) -- In the phenomenon of superlubricity, two solid surfaces can slide past each other with almost no friction. The effect occurs when the solid surfaces have crystalline structures and their lattices are rotated in such a way as to cancel out the friction force. A bit like stacking two egg cartons, if the lattices are aligned, they lock in to each other and it is hard to slide one over the other. But rotate one egg carton a bit, and it no longer locks in this way.

Scientists first observed superlubricity in graphite in 2004, and so far all experimental evidence of superlubricity has been obtained on the nanoscale and under vacuum conditions. Previous research even predicted that superlubricity breaks down on larger scales. But now in a new study, scientists have demonstrated that superlubricity in graphite can occur over microscale areas and under ambient conditions, which could open the way toward practical applications in micromechanical systems.

The researchers, led by Quanshui Zheng from Tsinghua University in Beijing and Nanchang University in Nanchang, China, and Jefferson Zhe Liu from Monash University in Clayton, Australia, have published their paper on the microscale superlubricity in graphite in a recent issue of Physical Review Letters.

“We are providing evidence of superlubricity on a much larger scale than previously – micro rather than nano – and the effect persists even in ambient conditions,” Zheng told Phys.org. “We were not aware of the previous work predicting breakdown of the effect at the time the first measurements were done – perhaps that was fortunate, as it did not dissuade us from trying!”

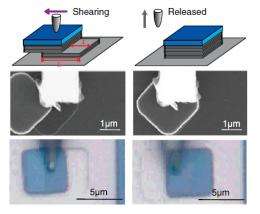

The most straightforward way to observe superlubricity is when two solid surfaces slide past each other. In the current study, the researchers developed a novel way of probing superlubricity by using a tungsten microtip to shear flakes from graphite slabs, or “mesas.” Upon release of shearing, some of the flakes spontaneously return to their original positions on the mesas, and this process of shearing and self-retraction can be repeated over and over.

The scientists explained that the self-retraction results from ultralow friction that occurs between the flake and mesa surfaces when oriented in a twisted, or incommensurate, way.

Although self-retracting flakes returned to their same positions and orientations as before shearing, the researchers could deliberately rotate sheared flakes before releasing them in order to create a commensurate orientation resulting in locked-in states, under which the flakes did not exhibit self-retraction. These locked-in states occur at some specific orientations exhibiting a 6-fold symmetry, but self-retraction still occurred when the mesas were sheared in all other directions.

When investigating the flakes that did not self-retract, the researchers found abrupt variations in the color of the sheared flakes, while the color of self-retracting flakes was uniform. They think that the color variation occurs due to optical interference resulting from thickness variations in the graphite mesas. Larger mesas have larger thickness variations, as well as a smaller probability of exhibiting self-retraction.

As the first evidence of reproducible superlubricity on the micron scale, and even under ambient conditions, the results could prove more useful for applications than superlubricity on the nanoscale. At the nanoscale, achieving superlubricity requires complex set-ups and sample preparation, and the effect can be easily suppressed by various mechanisms that cause twisting and lock-in. The new way of producing superlubricity on the microscale overcomes many of these barriers, and could be used to limit friction and wear in micromechanical systems.

“There are many micromechanical devices – for example motion sensors, radio-frequency generators, gyroscopes – where the relative motion of two parts is important,” Liu said. “Superlubricity opens a new avenue for creating such devices.”

The researchers plan to further explore the extent of superlubricity in the future.

“We are already working on several fronts: to study the superlubric motion in more detail, to explore the extensions of this to both larger and smaller scales, and to study the long-term robustness of the effect under different physical conditions,” said coauthor Francois Grey of Tsinghua University.

More information: Ze Liu, et al. “Observation of Microscale Superlubricity in Graphite.” PRL 108, 205503 (2012). DOI: 10.1103/PhysRevLett.108.205503

Journal information: Physical Review Letters

Copyright 2012 Phys.org

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.