September 20, 2011 feature

Graphene can be strengthened by folding

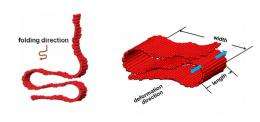

(PhysOrg.com) -- With a strength 200 times greater than that of steel, graphene is the strongest known material to exist. But now scientists have found that folding graphene nanoribbons into structures they call “grafold” can enable it to bear even greater compressive loads.

The researchers, Yongping Zheng and Zhigao Huang of Fujian Normal University in China; Ning Wei and Zheyong Fan of Xiamen University in China; and Lanqing Xu of both universities, have published their study in a recent issue of Nanotechnology.

“The results of this work provide a new route for tailoring the properties of graphene-based nanomaterials,” Zheng told PhysOrg.com. “Currently, many researchers and engineers are concerned with doping, alchemy, etc. We have demonstrated here that structure re-construction could also lead to interesting results.”

In their study, the researchers used molecular dynamics simulations to investigate grafold. They compared graphene with grafold in two areas: tension (the force that pulls the material apart) and compression (the force that pushes the material together). The ability to be both elongated and squeezed without damage is very helpful for engineering applications. However, as the researchers explain, graphene only has a high tensile strength; because of its two-dimensional nature, it is “soft” under compression and can’t be squeezed.

In contrast, the researchers’ simulations showed that grafold is “harder” than graphene and can withstand much larger amounts of compression (10-25 GPa depending on the structure of grafold compared with less than 2 GPa for graphene). While its compressive strength is significantly higher than that of graphene, grafold’s tensile strength approaches that of graphene. The Young’s modulus (a measure of elasticity) and fracture strain of grafold are a little lower than those of graphene. The scientists noted that several other materials can withstand greater compression than grafold, including carbon nanotubes, which can be both elongated and squeezed like grafold.

“As is well known, graphene can’t withstand any compression,” Zheng said. “Via folding, graphene transforms into grafold and can be compressed to a certain amount. Even when highly compressed, it won’t break down, just be squeezed into a shorter folded belt. Furthermore, the deformation is elastic. As we know, if the strength exceeds carbon nanotubes’ breaking point, it will crash and never return to its original form.”

Among grafold’s advantages is that folding a graphene nanoribbon to create grafold will be much easier than rolling it up to create a carbon nanotube. Plus, grafold’s mechanical properties can be tuned by the modifying the folding design, such as changing the size, shape, and number of folds.

Overall, the results of the simulations provide a new route for tailoring the properties of graphene-based nanomaterials, which could lead to advanced mechanical applications. The researchers hope to experimentally fabricate grafold in the near future.

“There could be versatile applications,” Zheng said. “Say, one could utilize the elastic and low-to-mid stiffness of grafold in applications where a large damping is required.”

More information: Yongping Zheng, et al. “Mechanical properties of grafold: a demonstration of strengthened graphene.” Nanotechnology 22 (2011) 405701 (9pp). DOI:10.1088/0957-4484/22/40/405701

Copyright 2011 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.