Carbon nanotube composites for enzymes and cosmetics

Japanese researchers have developed a low cost and efficient method for producing electrically conducting composites based on electrostatic adsorption of CNTs onto resin and ceramic particles for applications including enzymes and cosmetics.

Hiroyuki Muto and colleagues at Japan’s Toyohashi University of Technology (Toyohashi Tech) have developed an innovative method for producing CNT (carbon nano-tube) resin composite material that only requires 1/100 of the conventional amount of CNT additive to produce electrical conductivity in the composite material.

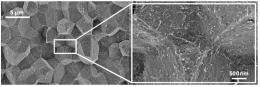

In this method, CNTs were mixed in an electrolyte solution and added to the composite, where the CNTs were adsorbed onto the surfaces of the resin particles due to electrostatic adsorption. This innovative procedure enabled the production of electrical conducting composites by the addition of a small quantity CNTs.

Importantly, the electrical conductivity of the composite material was easily controlled by changing the amount of electrolyte added to the composite; namely, the concentration of CNTs adsorption onto the resin particles.

Notably, this approach enables significant reductions in both the production costs and the production time compared with conventional methods for manufacturing conductive resins.

The researchers are confident that adding particles with charged surfaces will enable the production of a wide range of composite materials such as metals, ceramics, and polymers. This method is expected to find applications in the production of enzymes and cosmetics.

Provided by Toyohashi University of Technology