June 15, 2011 report

Research team develops method to produce large sheets of metamaterials

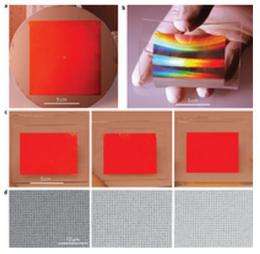

(PhysOrg.com) -- In an announcement many have been waiting for, a research team from the University of Illinois, has succeeded in figuring out how to produce metamaterials in a size big enough to be useful. The team, led by John Rogers, professor of materials engineering, describe in a paper published in Nature Nanotechnology, how they used a printing technique to stamp 3-D negative index metamaterials (NIMs) onto plastic or glass. The process could lead to the development of products such as extremely high resolution lenses; or as some hope, an invisibility cloak.

Metamaterials are materials that are able to bend light in ways that natural materials cannot; they can do so because they are made of layered materials with very tiny spaces in each layer such that when combined result in a mesh that is able to bend light in desired ways; sort of like taking several screen doors and laying them atop one another slightly out of line. As light hits the different parts of the screen, it is reflected in different directions. With metamaterials, the screen mesh holes are the size of the wavelengths of light, which is why until now, no one has been able to figure out how to create them in a size that could actually be used for something other than research.

The new process developed, changes all that. Instead of trying to create the metamaterials directly via electron beam etching, a stamp is first created; one that consists of lots of very small peaks and valleys. The stamp is then coated with a layer of a nondescript material that can be removed later, then covered over with layers of silver and magnesium fluoride. The mesh is created by causing just the coating from the peaks on the stamp to adhere to a glass or plastic sheet where the sacrificial layer is removed by etching, leaving just the mesh pattern.

Using this process the team was able to produce metamaterials a few square inches in size, constrained, they write, only by the apparatus they had available in the lab. Rogers reports that he and his team expect to soon produce materials several orders of magnitude larger.

The design, first envisioned by Xiang Zhang back in 2008, should be able to be used to produce sheets of new metamaterials of almost any size given the right resources, and what’s more should be able to do so in a reasonably economical manner, as the stamps are reusable. More research will still be needed however, before commercial products begin to appear because methods to create just the right kinds of stamps still need to be developed.

More information: Large-area flexible 3D optical negative index metamaterial formed by nanotransfer printing, Nature Nanotechnology (2011) doi:10.1038/nnano.2011.82

Abstract

Negative-index metamaterials (NIMs) are engineered structures with optical properties that cannot be obtained in naturally occurring materials. Recent work has demonstrated that focused ion beam and layer-by-layer electron-beam lithography can be used to pattern the necessary nanoscale features over small areas (hundreds of µm2) for metamaterials with three-dimensional layouts and interesting characteristics, including negative-index behaviour in the optical regime. A key challenge is in the fabrication of such three-dimensional NIMs with sizes and at throughputs necessary for many realistic applications (including lenses, resonators and other photonic components). We report a simple printing approach capable of forming large-area, high-quality NIMs with three-dimensional, multilayer formats. Here, a silicon wafer with deep, nanoscale patterns of surface relief serves as a reusable stamp. Blanket deposition of alternating layers of silver and magnesium fluoride onto such a stamp represents a process for ‘inking’ it with thick, multilayer assemblies. Transfer printing this ink material onto rigid or flexible substrates completes the fabrication in a high-throughput manner. Experimental measurements and simulation results show that macroscale, three-dimensional NIMs (>75 cm2) nano-manufactured in this way exhibit a strong, negative index of refraction in the near-infrared spectral range, with excellent figures of merit.

© 2010 PhysOrg.com