Curtains that 'quench' noise

Swiss researchers at Empa, in cooperation with textile designer Annette Douglas and silk weavers Weisbrod-Zürrer AG, have developed lightweight, translucent curtain materials, which are excellent at absorbing sound. This is a combination that has been lacking until now in modern interior design. And the new "noise-quenching" curtains have just gone onto the market.

Noise is annoying. It interrupts communication, reduces productivity and tires people out – in extreme cases it can even make them ill. Sound absorbing surfaces are therefore needed in rooms where people work, talk to each other or are trying to relax. These decrease reverberation and so make rooms quieter. However so called acoustically "hard" materials such as glass and concrete, which are commonly used in interior design, scarcely absorb sound at all. Heavy curtains made of material such as velvet are often used to absorb sound. On the other hand, lightweight and transparent curtains are acoustically almost useless. At least they were until now.

Together with industrial partner Weisbrod-Zürrer AG, a silk weaving company, and the textile designer Annette Douglas, Empa researchers have developed a new curtain fabric that is lightweight but still absorbs sound.

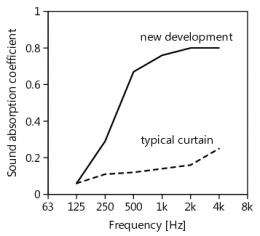

"Acousticians are pretty astonished when they see the readings we are achieving with the new curtains in the reverberation room. The weighted sound absorption coefficient is between 0.5 and 0.6», commented Kurt Eggenschwiler, Head of Empa's "Acoustics/Noise Control" Division. In other words, the new textiles «quench» five times more sound than conventional translucent curtains. Eggenschwiler continued: «The new curtain genuinely absorbs sound, noticeably improving the room acoustics – and its design is also very high quality."

A real gap in the market

Another advantage is that because the new curtains are translucent, they can be used in a variety of places such as offices, living rooms, restaurants, hotel lobbies, seminar rooms and even multi-purpose auditoriums. They are often the deciding factor in satisfying the acoustic requirements and regulations that apply to these rooms. Just shortly after their launch it became apparent that the new textiles are really filling a gap in the market, as interest in them is "massive" according to Eggenschwiler.

The idea of a curtain that absorbs noise while, at the same time, being lightweight and translucent, came from the textile designer Annette Douglas, who has worked with the interaction between sound and textiles for many years and received the Swiss Textile Design Award in 2005 for the project "Acoustic walls for open plan offices". In cooperation with researchers from Empa's "Acoustics/Noise Control" Division and silk weavers Weisbrod Zürrer AG, and with support from researchers from Empa's "Advanced Fibres" Division, she submitted an associated project to the Commission for Technology and Innovation (CTI) in 2010. Not a simple task, because thin and, therefore, translucent fabrics are normally poor sound absorbers.

The first acoustically optimised lightweight textile came into being on a computer. The Empa acousticians wanted to use the characteristics of this virtual textile in order to prepare a kind of "recipe" for material experts, which would enable them to specifically manufacture a fabric that could absorb sound. In addition, they first developed a mathematical model to illustrate both the microscopic structure of the fabric as well as its macroscopic composition. On the basis of numerous acoustic measurements made on various samples, specifically woven by Weisbrod-Zürrer, they were able to gradually optimise the acoustic properties of the fabric. Annette Douglas then succeeded in translating the new findings into weaving techniques. She chose yarns that gave the materials the necessary characteristics in terms of flammability and translucence and determined the weave structure, i.e. how the threads should be woven in and out of each other. Weisbrod-Zürrer then adjusted the sophisticated manufacturing process so that the industrially-made curtains actually displayed the required acoustic characteristics.

Provided by EMPA