Researchers produce nanowires easier, faster than before

Sometimes simpler is better. Engineering researchers at Texas A&M University have developed a new way to produce ultra-thin electricity-conducting wire that is simpler and faster than existing processes.

"Other methods used to produce nanowires use high temperatures and high pressure," said Subrata Kundu, a post-doctoral researcher in the research group of Hong Liang, an associate professor in Texas A&M's Department of Mechanical Engineering. "This method is much simpler and faster."

Kundu and Liang described the process in an article in the current issue of the journal Advanced Materials.

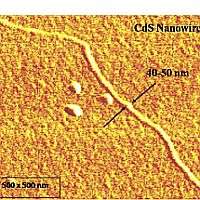

The process developed by Kundu and Liang works by shining ultraviolet light on a mixture of strands of DNA, cadmium sulfate and thioacetamide for about six hours. UV light breaks thioacetamide to produce sulfide ions (S2-). Chemical changes produced by the UV light allow the cadmium sulfate molecules to bind to the DNA. The resulting nanowires — about 1,000 times thinner than a human hair — conduct electricity and could be used in the development of so-called nano-scale electronic devices like small chips to make tiny computer or medical devices.

Nano-scale devices range in size from the size of a molecule to about 100 nanometers. One meter is 1 billion nanometers long.

Liang and Kundu plan to continue research in this area using different metals — lead, zinc and molybdenum — to produce the nanowires. Kundu said working with the other metals will give the researchers important information about how the process works.

The UV process also allows nanowires to be built on DNA arranged in two or three dimensions, t-joints and cubes, for example. This opens the possibility of using the process to build entire nano-scale circuits.

Source: Texas A&M University