This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

New research reveals mechanisms of stiffening in paper pulp, could lead to improved recyclability

One of the problems with paper recycling is that the fibers stiffen during the dewatering and drying processes, also known as hornification. The same thing happens to dishcloths, for example; they stiffen over time. New research can now explain the mechanisms of hornification, knowledge that will enable us to recycle paper fibers many more times compared to the current limit of between five and seven times.

The work is published in the journal Cellulose.

"Through our studies, we now know at what level of dryness the hornification process begins, already at a dry content of 20 percent," says Björn Sjöstrand, Docent in Chemical Engineering from The Swedish Research Council.

"We also know at what temperatures hornification begins, already at temperatures as low as 40° C, but the biggest changes are seen at temperatures above 100° C. The solvent also plays a role; if we replace the water in the paper pulp with other solvents, it reduces the hornification. This implies that the hydrogen bonds that form in the water environment contribute to the hornification of the fibers."

The research findings were presented during Ekmandagarna 2024, an annual conference organized by the Swedish Association of Pulp and Paper Engineers (SPCI). The findings can also be found in several newly published scientific papers.

"It was a great honor to have the opportunity to present our results at this year's Ekmandagarna, which brings together many participants from across the paper industry, both academics and industry representatives. Our hope is that this research can contribute to improved paper recycling where the fibers can be recycled many more times," says Sjöstrand. "In addition, this new knowledge of the hornification process can lead to reduced use of raw materials in paper manufacturing, as it allows for closer control of the durability properties of paper materials."

Greater insight into the process of hornification has many advantages. The research can hopefully contribute to new dewatering processes for the industry, which in turn will create more recycling opportunities and improved product properties.

Paper engineers are hopeful that it will be possible to circulate the fiber up to 25 times, compared to five to seven times today. The most important areas where knowledge of hornification can be applied are market pulp, dry broke, recycling, dissolving pulp and micro- and nano-cellulose applications.

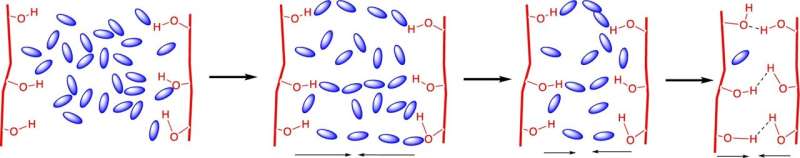

The research provides new insights into hornification, a research area with the potential to provide more opportunities for the forest industry to understand the changes in the binding capacity of wood fibers during the dewatering process. Hornification is when chemical bonds occur inside the fibers.

This prevents the fibers from swelling and reduces their flexibility and external fibrils. Flexible fibers and external fibrils are important for developing strength properties when manufacturing cardboard and paper.

"By using fewer fibers but still retaining the same level of mechanical performance in the products, you get a more optimized utilization of the raw materials," says Sjöstrand. "This means that the results of our project will contribute to both increased recycling and more sustainable use of resources."

More information: Mozhgan Hashemzehi et al, Degrees of hornification in softwood and hardwood kraft pulp during drying from different solvents, Cellulose (2024). DOI: 10.1007/s10570-023-05657-z

Provided by The Swedish Research Council