This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Overcoming fine process limits with linker ion affinity

A research team has employed linker ions to pioneer a three-dimensional microprinting technology applicable to inorganic substances and other various materials. The work is published in the journal Nature Communications.

Three-dimensional microprinting is a cutting-edge process used in electronic communications, biotechnology, health care and many other areas, and represents the next generation of manufacturing small components and sensors, aligning with the recent trends of device miniaturization and lightweight design. However, traditional 3D microprinting has faced challenges in maintaining structures, particularly with inorganic materials such as metals, where controlling nano-sized particles proved difficult.

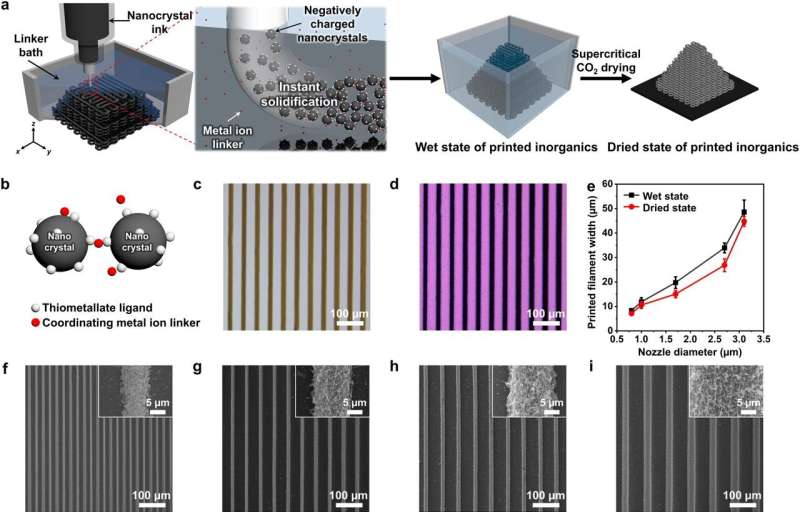

To address this challenge, the research team adopted transition metal cations as linker ions in their recent study. Linker ions selectively react on the surfaces of nanoparticles and promote bonding and interactions among particles, inducing their rapid solidification.

The team employed 3D microprinting technology to deposit inorganic nanoparticles into a linker ion bath. The linker ions caused the formation of interconnected networks among the dispersed inorganic nanoparticles, allowing the particles to solidify and maintain the overall structure rapidly.

Moreover, the team managed to craft inorganic porous structures with dimensions below 10 μm by fine-tuning the interactions between particles, surpassing the limitations of conventional microprinting and achieving inorganic material printing without the need for specialized equipment.

This research showcases the versatility of their technology, demonstrating its applicability to a wide range of functional inorganic materials, including metals, semiconductors, magnets, and oxides. Significantly, their method holds promise for replacing the conventional high-cost and time-consuming processes in manufacturing components for electronic devices, such as micro-electro-mechanical systems (MEMS).

Pohang University of Science and Technology Professor Jae Sung Son remarks, "Our research introduces a new pathway for effortlessly creating three-dimensional structures with improved solution processing technology for nano-printing. It is poised to play a crucial role in further research on nano-material-based devices."

Dr. Jin Young Kim, from the Korea Institute of Science and Technology, says, "We look forward to the commercialization of various materials and components made possible by the improved quality of large-area structures and enhanced production speed brought about by our process technology."

More information: Minju Song et al, 3D microprinting of inorganic porous materials by chemical linking-induced solidification of nanocrystals, Nature Communications (2023). DOI: 10.1038/s41467-023-44145-7

Journal information: Nature Communications

Provided by Pohang University of Science and Technology