This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Greener and feasible production: Enzymatic methods for mono- and diacylglycerol synthesis in the food industry

MAGs, predominantly in 1(3)-MAG form, and DAGs, with 1,3-DAGs as the more stable isomer, are crucial in food, cosmetic, and other industries. While MAGs are vital emulsifiers, comprising 75% of global production, DAGs are known as functional cooking oils that can reduce body fat and serum TAGs. However, their natural concentration in oils is low, prompting extensive research into their chemical and environmentally friendly enzymatic production.

Recently, a review published in Grain & Oil Science and Technology has shed light on the advancements in enzymatic production methods with special efforts on practical and industrial technologies such as comprehensive discussions on system designs and patent evaluations.

This study presents these methods as a sustainable and efficient alternative to conventional chemical processes, emphasizing their role in revolutionizing industry standards.

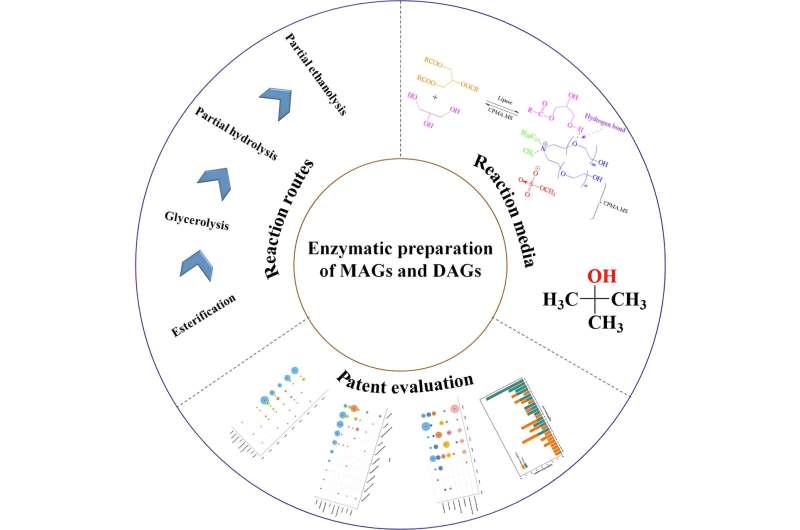

This review presents an in-depth review of the last 15 years in enzymatic production of monoacylglycerols (MAGs) and diacylglycerols (DAGs), focusing on the advancements and varied pathways like esterification, glycerolysis, and more. It emphasizes how enzyme choice, substrates, and conditions affect the efficiency and quality of MAGs and DAGs, highlighting the role of reaction media in enhancing reaction homogeneity and product yield.

The review also explores the practicalities of scaling enzymatic processes for industrial use, discussing the challenges of maintaining enzyme activity and the economic implications of enzyme use. Additionally, it evaluates numerous patents, reflecting a growing interest in this eco-friendly technology.

The review underlines the transformative potential of enzymatic production in delivering higher quality, more sustainable MAGs and DAGs while acknowledging the ongoing challenges and the need for further innovation in this field.

The review's authors, Jiawei Zheng and colleagues, underscore the industry's increasing shift towards enzymatic processes over the past two decades. They note, "Enzymatic methods are not just alternatives but are becoming the standard due to their specificity, lower energy requirements, and ability to preserve sensitive components."

Transitioning to enzymatic production has vast implications for the food industry, offering safer and more sustainable emulsifiers and cooking oils. The ability to control reaction specifics leads to higher quality products, meeting consumer demands for healthier and more natural food ingredients. From the discussion of the practical considerations of technologies and potential possibilities, a reasonable economy for the production in plants can be expected.

The review anticipates further industry adoption and innovation in enzyme technologies. However, it also calls for continued research to overcome challenges like reaction efficiency and large-scale application, ensuring that enzymatic methods can fully meet global demand.

More information: Jiawei Zheng et al, Enzymatic preparation of mono- and diacylglycerols: A review, Grain & Oil Science and Technology (2023). DOI: 10.1016/j.gaost.2023.10.002

Provided by Chinese Academy of Sciences