This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Combining atomistic simulations and machine learning to predict grain boundary segregation in magnesium alloys

Magnesium alloys hold promise as a lightweight material to reduce weight in automobiles and transportation systems, offering potential to enhance fuel economy and reduce emissions, but low formability and strength prevent widespread adoption.

Researchers at the University of Michigan have developed a predictive model to aid magnesium alloy optimization to overcome these challenges.

Understanding and manipulating interactions between solute elements and grain boundaries at various temperatures is crucial for determining the optimal magnesium alloy compositions and processing routes. As the rare-earth element yttrium exhibits the ability to segregate magnesium grain boundaries, the study developed the model based on yttrium effects on magnesium alloys.

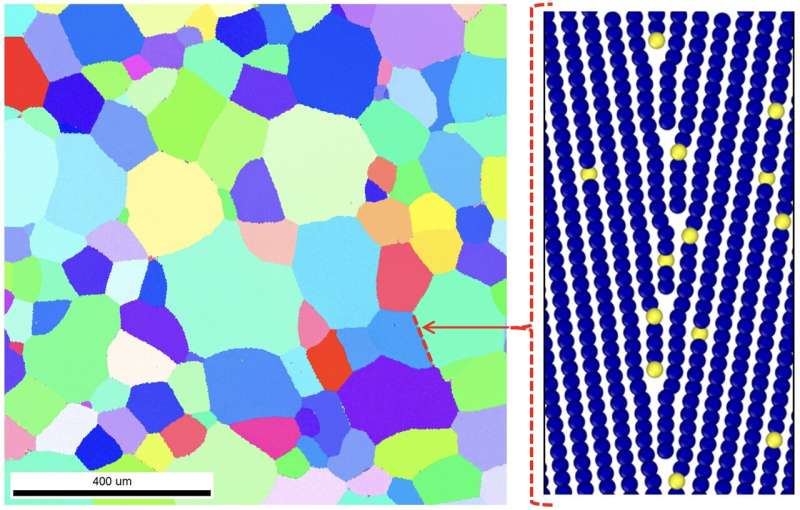

The paper published in Acta Materialia describes an integrated method based on atomistic simulations and machine learning to accurately predict equilibrium solute segregation behavior to grain boundaries in micro-scale polycrystalline magnesium alloys at high temperatures representative of their thermomechanical processing.

"This approach allows accurate considerations of the statistical features of grain boundary sites and finite-temperature effects beyond the harmonic approximation on solute segregation energetics," said Liang Qi, an associate professor of material science and engineering and corresponding author on the paper.

When constructing the predictive model, the researchers integrated the spectral model for grain boundary segregation, thermodynamic integration based on molecular dynamics simulations for accurate free energy calculations, and physics-informed machine-learning surrogate models with rigorous uncertainty analysis.

"Our surrogate model demonstrates robustness in predicting the segregation free energy for grain sites that deviate significantly from those encompassed in our training data set," said Vaidehi Menon, a doctoral student in material science and engineering and first author on the paper

Co-authors Sambit Das, an assistant research scientist, and Vikram Gavini, a professor of mechanical engineering and materials science and engineering, applied their software, capable of calculating interactions among electrons, to perform first-principles calculations to verify the accuracy of atomistic simulations.

Although models were based on yttrium, this rare-earth element would incur significant costs in large-scale structural applications. The comprehensive predictive tool developed by the research team can help to identify more practical alloying elements.

"Our method can help accelerate the identification of cost-effective alloying elements to improve magnesium alloys and other metallic alloy systems," said Qi.

More information: Vaidehi Menon et al, Atomistic simulations and machine learning of solute grain boundary segregation in Mg alloys at finite temperatures, Acta Materialia (2023). DOI: 10.1016/j.actamat.2023.119515

Journal information: Acta Materialia

Provided by University of Michigan College of Engineering