This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Cow manure to synthetic gas: How can we optimize the process?

The overuse of fossil fuels has led to pollution that has become a globally recognized environmental problem. Therefore, adjusting the energy structure and gradually reducing the use of traditional fossil fuels such as oil and coal while developing green, low-carbon, and sustainable energy sources has become a hot topic in recent years.

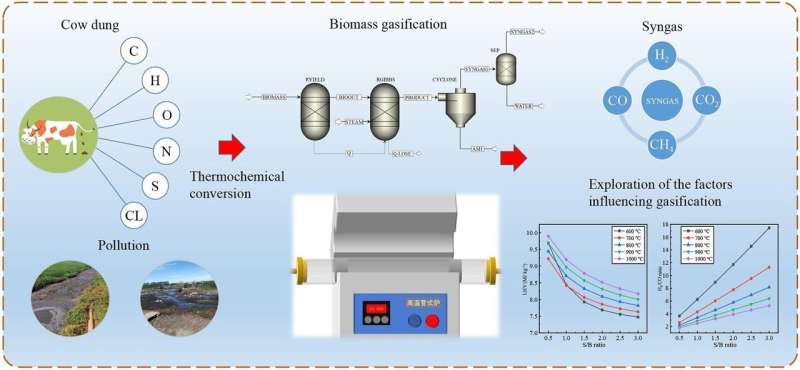

Biomass energy is one of the alternative energy sources to fossil fuels and is considered a clean and renewable energy source. Using biomass as an energy source can effectively reduce the emissions of harmful gases such as CO2, NOx, and SOx. Biomass refers to various organic materials produced through photosynthesis, including crops, trees, animals, organic waste, and livestock and poultry manure, among others. Among different types of biomass, livestock and poultry manure contribute to environmental pollution in several aspects, including water pollution, air pollution, and soil pollution.

In recent years, there have been various methods for treating livestock and poultry manure, including feed recycling technology, microbial fermentation utilization technology, and fertilizer utilization technology. However, these treatment methods have longer processing cycles, are susceptible to environmental influences, and have low efficiency. With the development of large-scale livestock farming industries in recent years, a significant amount of livestock and poultry manure is generated. Therefore, thermal chemical treatment of livestock and poultry manure has become a promising option.

There have been significant advancements in the thermal chemical treatment of livestock and poultry manure. Gasification is a crucial thermal chemical process that converts biomass raw materials into a gas fuel under high-temperature incomplete combustion conditions. The ultimate product of gasification is syngas, which primarily consists of CO2, CO, H2, CH4 and other gases.

Syngas can be used in various energy conversion devices, such as internal combustion engines, gas turbines, and fuel cells. Gasification can be categorized into different types based on the gasification agent, including air gasification, steam gasification, and CO2 gasification. Gasification generally involves two processes: pyrolysis, in which biomass is heated to release volatile compounds and form char, and gasification, in which char reacts with the gasification agent to produce syngas.

Livestock and poultry manure, as waste products of animal husbandry, have the advantage of being less affected by weather and seasonal variations compared to other biomass sources. Additionally, livestock and poultry manure is highly renewable and abundant. It often has a high moisture content, which can effectively promote steam gasification, leading to higher hydrogen gas production. Therefore, using livestock and poultry manure as a gasification feedstock holds great promise and can effectively mitigate environmental pollution caused by fossil fuels.

The optimization of various parameters during the gasification process is crucial. However, the complexity and variability of gasification processes make the structure of gasification equipment complex in experimental setups. Furthermore, the process is influenced by on-site experimental conditions and limitations of gasification equipment, making it difficult to fully understand gasification characteristics. Analytical and predictive simulation methods can effectively compensate for inherent deficiencies in experimental systems.

A team of researchers led by Professor Hu Jianjun from Henan Agricultural University, including graduate student Zhang Yajun and Associate Professor Yao Sen, used Aspen Plus software to establish a biomass gasification model for the thermal decomposition gasification process of cow manure, based on Gibbs free energy minimization. The study is published in the journal Frontiers of Agricultural Science and Engineering.

They evaluated the H2/CO ratio and lower heating value (LHV) of the obtained syngas (also known as synthesis gas) by changing parameters such as gasification temperature, steam-to-biomass ratio, and pressure. Simulation results showed that an increase in gasification temperature favored the enhancement of H2 and CO content, with H2 reaching its peak at 800 °C. Increasing steam as a gasification agent led to higher H2 production.

However, the steam-to-biomass ratio had a negative impact on CO and CH4, resulting in a decrease in LHV. The optimal gasification pressure was found to be 0.1 MPa. This model can also be used for predicting syngas composition from other biomass feedstocks and allows for further research on improving biomass gasification processes.

More information: Yajun Zhang et al, Numerical modeling of biomass gasification using cow dung as feedstock, Frontiers of Agricultural Science and Engineering (2023). DOI: 10.15302/J-FASE-2023500

Provided by Frontiers Journals