This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Research team reports on discovery of grain-interior planar defects induced by heteroatom monolayer

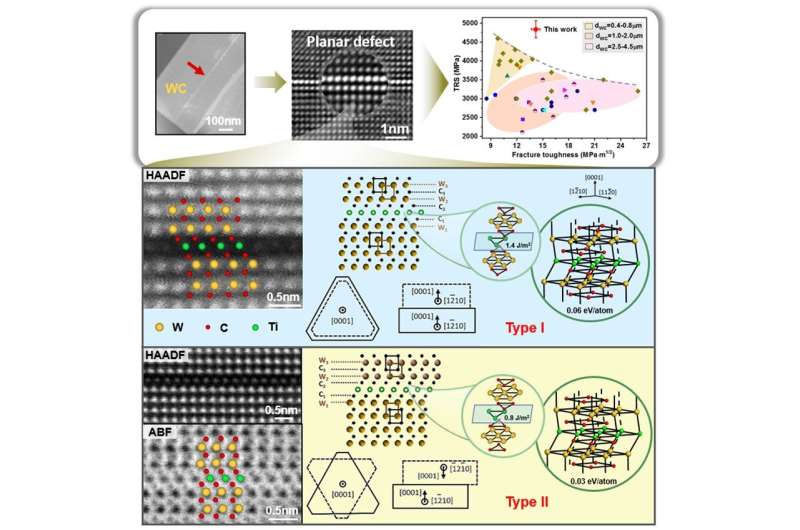

In collaboration with the Institute of Physics at the Chinese Academy of Sciences (IPCAS), researchers from Beijing University of Technology (BJUT) have discovered a new type of grain-interior planar defect in a ceramic phase in TiC doped cemented tungsten carbides.

These planar defects were found to be a result of the ordered distribution of heteroatoms on specific crystal planes of tungsten (W) and carbon (C). Importantly, these newly identified defects display distinct characteristics that set them apart from known planar defects, such as phase boundaries, grain boundaries, twin boundaries, stacking faults and complexions.

The work is published in Advanced Powder Materials, and involved detailed characterizations on the atomic scale for the composition, structure and crystallography of the new type of planar defects. In addition, comprehensive model calculations were conducted to assess the defects' energy state and stability, providing further insights into their nature.

The research team, led by Professor Xiaoyan Song from BJUT, found that the occurrence of titanium (Ti) monolayer on the basal planes of WC was caused by the destabilization of (W,Ti)Cx complexions, which formed at the WC/Co interfaces by dissolution-precipitation processes during sintering of the powder mixture. The stable Ti monolayer may provide nucleation sites for the growth of WC crystal along the [0001]WC direction. This possibility was confirmed by model calculations.

"We further explored the possibility for the formation of such planar defects in WC grains by doping of V, Zr, Nb, Mo, and Hf through modeling," explained Song. "We found that the Ti-monolayer induced planar defects had the highest stability in the WC grain interior, and also were much easier to form in the cemented carbides."

The work highlights the significance of planar defects with high stability hindering the long-distance motion of stacking faults and dislocations within grains, and act as obstructions against propagation of the transgranular cracks. Thus, the risk of transgranular fracture, which is the dominant failure mode of the covalent crystals in ceramics and ceramic matrix composites, can be significantly reduced.

"We conclusively demonstrated that adjusting the density of planar defects allows for optimal mechanical performance, striking an exceptional balance between strength and fracture toughness in the materials," added Song. "Our study paves the way for improving the mechanical properties of materials through the deliberate introduction and customization of heteroatomic monolayer-induced grain-interior planar defects."

Furthermore, the methodology described in this article, using cemented tungsten carbides as a representative case, can be extended to other materials. By carefully selecting dopants and controlling sintering parameters, it becomes possible to fine-tune the density of planar defects to achieve desired properties in various ceramic systems.

More information: Xingwei Liu et al, Grain-interior planar defects induced by heteroatom monolayer, Advanced Powder Materials (2023). DOI: 10.1016/j.apmate.2023.100130

Provided by KeAi Communications Co.