This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Laser direct writing of Ga2O3/liquid metal-based flexible humidity sensors

Recent studies in emerging flexible humidity sensors have achieved great developments in advanced manufacturing methods, as well as innovative applications including human health care detection, plant health management and noncontact human-machine interfaces. Capacitive-type humidity sensors have gained much attention due to reliable humidity sensing performance, low power consumption and facile structural designs. Generally, the performance of a capacitive humidity sensor is strongly correlated with the dielectric permittivity of functional materials between sensing electrodes.

Up to now, various active materials have been investigated as flexible capacitive humidity sensors, such as carbon materials, metal oxides, metal sulfides, and polymers. Similarly, they are typically endowed with large exposed surface areas and rich active sites to interact with water molecules. Ga2O3, as a potential metal oxide with high exposed hydrophilic groups, has been employed as an active material for capacitive humidity sensors.

Traditional fabrication techniques to obtain Ga2O3-based humidity sensors mainly involve chemical vapor deposition, thermal treatment, and hydrothermal methods. Nevertheless, these methods usually require high annealing temperature, complicated fabrication procedures as well as various material systems, hindering their practical applications.

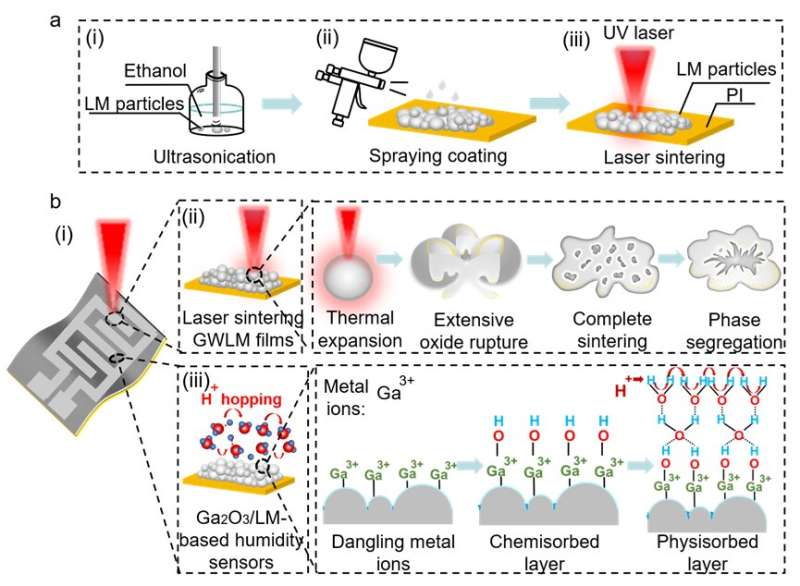

Digital laser direct writing is a rapid and environmental-friendly manufacturing approach to generating functional micro/nano-structures or directly creating sensitive nanomaterials with high precision. Based on laser-matter interactions, via judiciously selecting the appropriate laser processing parameters, a variety of innovative flexible sensors, such as physical, chemical and physiological sensors have been demonstrated.

The typical strategies usually rely on the laser direct writing of electrodes, followed by the deposition of moisture sensitive nanomaterials, such as carbon or metal sulfides-based materials, on the top of electrodes. However, this leads to multiple complex procedures. Therefore, a facile and simple approach to developing thin film-based humidity sensor is still required.

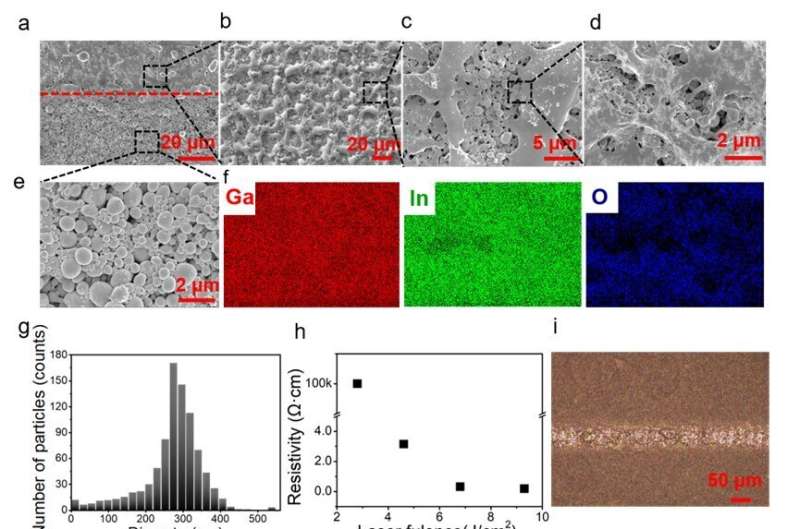

In this new work, published in Opto-Electronic Advances, a wearable capacitive-type Ga2O3/liquid metal-based humidity sensor is demonstrated by a one-step laser direct writing technique. Due to the photothermal effect of laser, the Ga2O3-wrapped liquid metal nanoparticles can be selectively sintered and converted from insulative to conductive traces with a resistivity of 0.19 Ω·cm, while the untreated regions serve as active sensing layers in response to moisture changes.

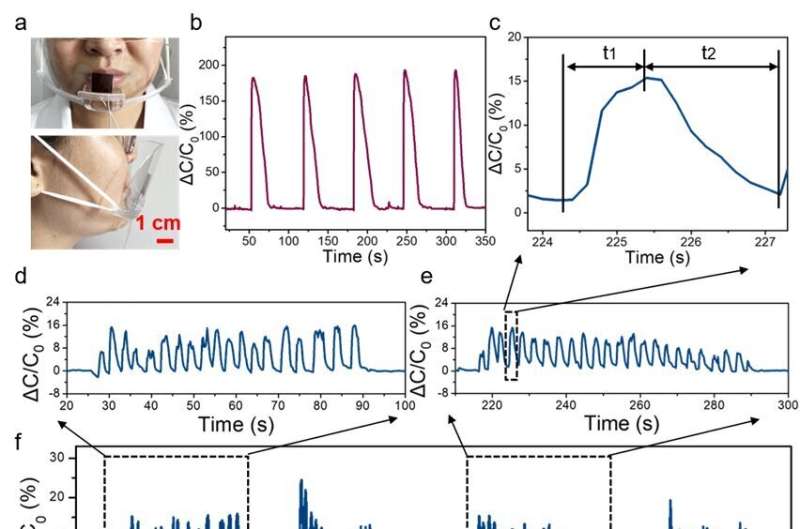

Under 95% relative humidity, the humidity sensor displays a highly stable performance along with rapid response and recover time. Utilizing these superior properties, the Ga2O3/liquid metal-based humidity sensor is able to monitor human respiration rate, as well as skin moisture of the palm under different physiological states for health care monitoring.

More information: Songya Cui et al, Laser direct writing of Ga2O3/liquid metal-based flexible humidity sensors, Opto-Electronic Advances (2023). DOI: 10.29026/oea.2023.220172

Provided by Compuscript Ltd