April 27, 2023 report

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Using electrified spatiotemporal heating to depolymerize plastics

A team of engineers and materials scientists affiliated with multiple institutions in the U.S., has developed a new way to depolymerize plastics using electrified spatiotemporal heating. In their paper, published in the journal Nature, the group describes the new process and its efficiency. Nature has also published a Research Briefing in the same journal issue outlining the work done by the team.

Over the past several years, plastic pollution has become a major concern, both for the environment and for the health of plants and animals, including humans, and scientists are seeking ways to recycle it. Most of the techniques developed thus far involve using chemicals to depolymerize plastics. These efforts are still extremely inefficient, however, with yields between 10% and 25%. In this new effort, the team has found a way to use pulsed electricity to boost the yield to approximately 36%.

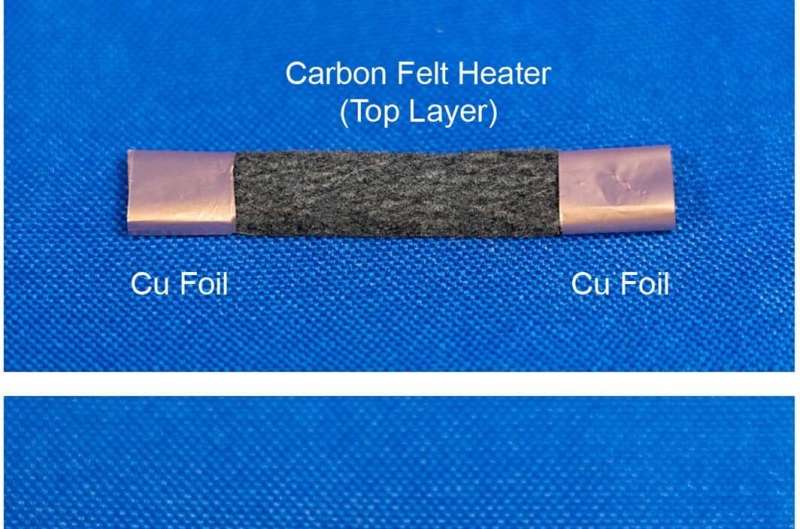

The approach involved designing a new kind of reactor with a porous carbon felt bilayer and a pulsed electric heater at the top. In their reactor, plastic bits are melted as they are fed in to the upper chamber and flow as a mass into a lower chamber, where the material is pushed through the felt filter. The plastic then begins to decompose as the temperature rises. As the molecules that make up the plastic become smaller, their volatility grows until they are expelled from the reactor as a gas, which allows more liquid to be drawn in. Using electricity to heat the plastic allows for oscillating the temperature, allowing simpler depolymerization reactions to take precedence over side reactions, which need additional heating to depolymerize.

In addition to improving efficiency, the new approach uses less energy because of the oscillating instead of constant heat source. The team notes the system could be made more eco-friendly by using renewable sources for the electricity. They note that their reactor does emit other materials, such as acetylene, methane and some larger molecules, along with some aromatics. They also acknowledge that more work is required to reduce the amount of carbon released during the reactions.

More information: Qi Dong et al, Depolymerization of plastics by means of electrified spatiotemporal heating, Nature (2023). DOI: 10.1038/s41586-023-05845-8

Benjamin Thompson et al, A smarter way to melt down plastics?, Nature (2023). DOI: 10.1038/d41586-023-01348-8

Journal information: Nature

© 2023 Science X Network