This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Deepfreeze electronics for supercomputers—technology prepares quantum computing for industrial use

Quantum computers are highly energy-efficient and extremely powerful supercomputers. But for these machines to realize their full potential in new applications like artificial intelligence or machine learning, researchers are hard at work at perfecting the underlying electronics to process their calculations. A team at Fraunhofer IZM are working on superconducting connections that measure a mere ten micrometers in thickness, moving the industry a substantial step closer to a future of commercially viable quantum computers.

With the extreme computing power they promise, quantum computers have the potential to become the driving force for technological innovations in all areas of modern industry. By contrast with the run-of-the-mill computers of today, they do not work with bits, but with qubits: No longer are these units of information restricted to the binary states of 1 or 0.

With quantum superposition or entanglement added, qubits mean a great leap forward in terms of sheer speed and power and the complexity of the calculations they can handle. One simple rule still holds, though: More qubits mean more speed and more computing power.

There seems no end to the possible uses for quantum computers: Wherever massive datasets like simulations or probability calculations have to be processed, they can solve even complicated problems at lightning speed. From optimized logistics or traffic management due to highly precise forecasts or from the production of novel medical treatments with precisely modeled molecules to virtually unbreakable encryptions for the finance industry, everything seems possible.

The transition to the new technological age seems only a quantum leap away, but it is not as simple as that. The quantum computers of the first two generations have taught researchers a lot about the fundamental workings of the new technology. The flagships of this new fleet of supercomputers, like the quantum computer at the Jülich Research Centre, currently work with a respectable 5,000 qubits, meaning 25000 potential states for every quantum particle.

But these machines are coming up against certain limitations: The complex interplay of connected qubits is extremely sensitive to disruption, which can mean faults and errors in the calculations. They need error correction mechanisms to polish the results, which in turn need far more qubits than the original calculation: Researchers are expecting future quantum computers to have at least 100,000 or even a million qubits each.

To achieve this number of qubits in a single system, new integrated circuits and connections have to be developed that work at extreme levels of miniaturization and can stand temperatures as low as -273° C. It is in these unimaginably freezing conditions that the lattice vibration in solid bodies slows down enough for the qubits to remain entangled and to be readable.

But the system is at risk of warming itself up with its own power, which is why lossless superconductors are used at the lowest possible temperatures. Designing and building these superconducting connections for such systems and the cryogenic packaging they need is the mission of Dr. Hermann Oppermann at Fraunhofer IZM in Berlin.

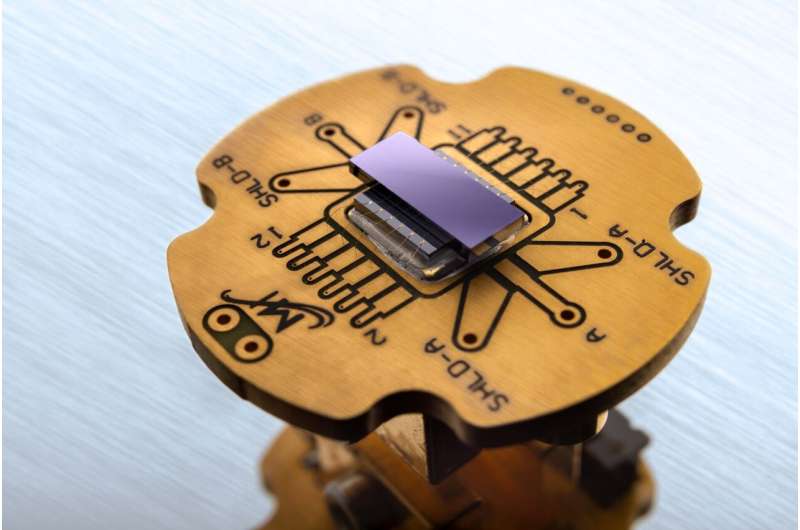

For his team to create the necessary solder contacts or bumps that can cope with extremely low temperatures, they had to come up with a new technology. They chose indium for the purpose, a material that becomes superconducting at below 3.4 Kelvin and stays robust even near absolute zero temperatures.

To create electronic structures from indium, the material is electroplated using special electrolytes. This process requires the indium to be moved from the nickel base that is commonly used for structures of these dimensions. Nickel would produce too strong a magnetic field that might disrupt the work of the qubits, whereas the new metallized base works as a seed layer for the electroplating.

The process used by the team meant a new world record in miniaturization for cryogenic connections, with the grid spacing of the connectors reduced to less than 10 micrometers.

The team also constructed extremely low-loss, superconducting connectors from niobium and niobium nitride. An innovative process was developed for the niobium coating that was then etched by ion ray to create compact connectors in an exceptional alloy that work at cryogenic temperatures and can handle high current densities. After the indium bumps and the superconducting circuit carriers were finished, the components were subjected to temperatures below 3 Kelvin in a special cryogenic test—successfully.

Provided by Fraunhofer-Institut für Zuverlässigkeit und Mikrointegration IZM