Direct production of olefins from syngas with ultrahigh carbon efficiency

Olefins are key building blocks to manufacture a wide range of value-added products such as polymers, lubricants, plasticizers, drugs, detergent and cosmetics.

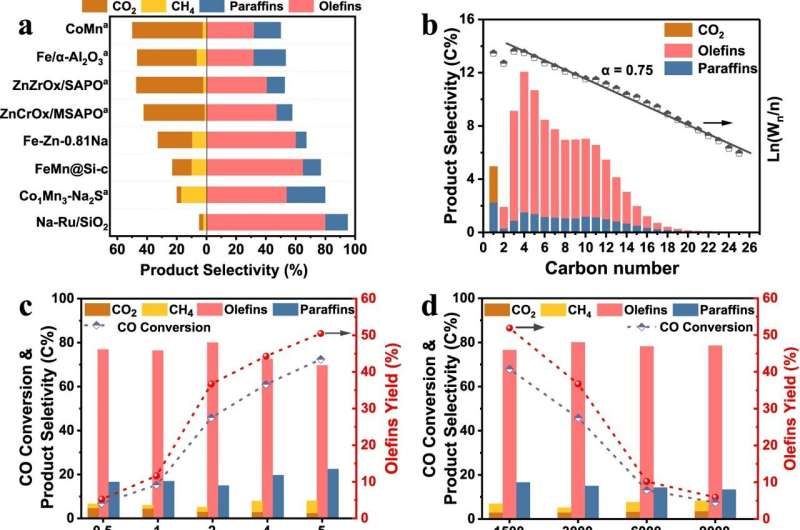

Syngas conversion serves as a competitive strategy to produce olefins from nonpetroleum resources. However, the goal to achieve desirable olefins selectivity with limited undesired C1 by-products remains challenging.

Recently, a research team led by Prof. Zhong Liangshu from the Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences has reported a non-classical Fischer-Tropsch to olefins (FTO) process, which can realize 80.1% olefins selectivity with ultralow total selectivity of CH4 and CO2 (<5%) at CO conversion of 45.8%.

The results were published in Nature Communications on Oct. 10.

The researchers prepared a silica-supported Ru nanoparticles catalyst with sodium (Na) as promoter (denoted as Na-Ru/SiO2), which was highly active for FTO reaction but very inactive for water-gas-shift (WGS) reaction.

They further found that the Ru metal was the active phase, and the Na promoter could suppress the reactivity of chemisorbed H atoms on Ru surface sites while greatly promote the production of olefins, especially for long-chain α-olefins, whose fraction in olefins distribution reached up to 74.5%.

No obvious deactivation was observed within 550 hours and the pellet catalyst also exhibited excellent catalytic performance in a pilot-scale reactor, suggesting promising practical applications.

The results of this work demonstrate that the modified-metallic Ru can effectively tune the dominated product distribution from traditional paraffins to value-added olefins. The as-obtained catalytic performance exhibits the highest olefins (especially for long-chain α-olefins) selectivity and yield together with the lowest fraction of undesired C1 by-products including CH4 and CO2, which outperforms the reported results under all the CO conversion levels in previous references.

More information: Hailing Yu et al, Direct production of olefins from syngas with ultrahigh carbon efficiency, Nature Communications (2022). DOI: 10.1038/s41467-022-33715-w

Journal information: Nature Communications

Provided by Chinese Academy of Sciences