Technology produces more than 100 medical microrobots per minute that can be disintegrated in the body

Daegu Gyeongbuk Institute of Science & Technology (DGIST, President Yang Kook) Professor Hongsoo Choi's team of the Department of Robotics and Mechatronics Engineering collaborated with Professor Sung-Won Kim's team at Seoul St. Mary's Hospital, Catholic University of Korea, and Professor Bradley J. Nelson's team at ETH Zurich to develop a technology that produces more than 100 microrobots per minute that can be disintegrated in the body.

Microrobots aiming at minimal invasive targeted precision therapy can be manufactured in various ways. Among them, ultra-fine 3D printing technology called two-photon polymerization method, a method that triggers polymerization by intersecting two lasers in synthetic resin, is the most used. This technology can produce a structure with nanometer-level precision. However, a disadvantage exists in that producing one microrobot is time consuming because voxels, the pixels realized by 3D printing, must be cured successively. In addition, the magnetic nanoparticles contained in the robot can block the light path during the two-photon polymerization process. This process result may not be uniform when using magnetic nanoparticles with high concentration.

To overcome the limitations of the existing microrobot manufacturing method, DGIST Professor Hongsoo Choi's research team developed a method to create microrobots at a high speed of 100 per minute by flowing a mixture of magnetic nanoparticles and gelatin methacrylate, which is biodegradable and can be cured by light, into the microfluidic chip. This is more than 10,000 times faster than using the existing two-photon polymerization method to manufacture microrobots.

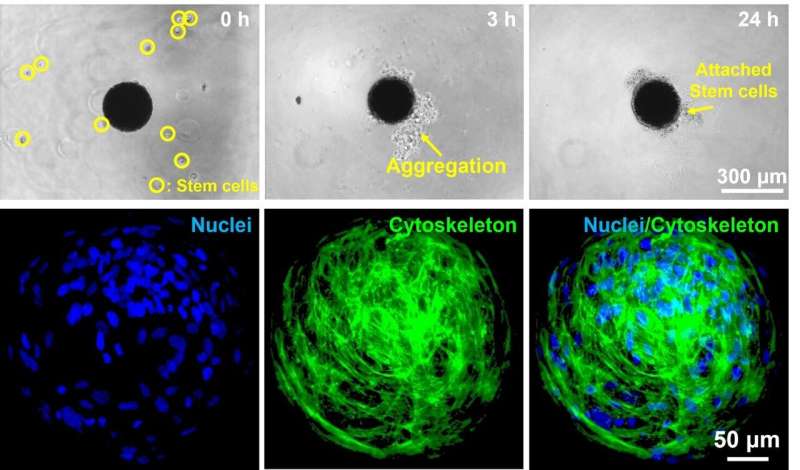

Then, the microrobot produced with this technology was cultured with human nasal turbinated stem cells collected from human nose to induce stem cell adherence to the surface of the microrobot. Through this process, a stem cell carrying microrobot, including magnetic nanoparticles inside and stem cells attached to the exterior surface, was fabricated. The robot moves as the magnetic nanoparticles inside the robot respond to an external magnetic field and can be moved to a desired position.

Selective cell delivery was difficult in the case of the existing stem cell therapy. However, the stem cell carrying microrobot can move to a desired location by controlling the magnetic field generated from the electromagnetic field control system in real time. The research team conducted an experiment to examine whether the stem cell carrying microrobot could reach the target point by passing through a maze-shaped microchannel, and consequently confirmed that the robot could move to the desired location.

In addition, the degradability of the microrobot was evaluated by incubating the stem cell carrying microrobot with degrading enzyme. After 6 hours of incubation, the microrobot was completely disintegrated, and the magnetic nanoparticles inside the robot were collected by the magnetic field generated from the magnetic field control system. Stem cells were proliferated at the location where the microrobot was disintegrated. Subsequently, the stem cells were induced to differentiate into nerve cells to confirm normal differentiation; the stem cells were differentiated into nerve cells after approximately 21 days. This experiment verified that delivering stem cells to a desired location using a microrobot was possible and that the delivered stem cells could serve as a targeted precision therapeutic agent by exhibiting proliferation and differentiation.

Furthermore, the research team confirmed whether the stem cells delivered by the microrobot exhibited normal electrical and physiological characteristics. The final goal of this study is to ensure that the stem cells delivered by the robot normally perform their bridge role in a state where the connection between the existing nerve cells is disconnected. To confirm this, hippocampal neurons extracted from rat embryo that stably emit electrical signals were utilized. The corresponding cell was attached to the surface of the microrobot, cultured on a micro-sized electrode chip, and electrical signals were observed from the hippocampal neurons after 28 days. Through this, the microrobot was verified to properly perform its role as a cell delivery platform.

DGIST Professor Hongsoo Choi said, "We expect that the technologies developed through this study, such as mass production of microrobots, precise operation by electromagnetic fields, and stem cell delivery and differentiation, will dramatically increase the efficiency of targeted precision therapy in the future."

Meanwhile, the results of this study were published on June 23 in the scientific journal Small .

More information: Seungmin Noh et al, A Biodegradable Magnetic Microrobot Based on Gelatin Methacrylate for Precise Delivery of Stem Cells with Mass Production Capability, Small (2022). DOI: 10.1002/smll.202107888

Journal information: Small

Provided by DGIST (Daegu Gyeongbuk Institute of Science and Technology)