Simple silicon coating solves long-standing optical challenge

Quick bursts of laser light, lasting less than a trillionth of a second, are used in a range of applications today. These ultrashort laser pulses have allowed scientists to observe chemical reactions in real-time, image delicate biological samples, build precise nanostructures, and send long-distance, high-bitrate optical communications.

But any application of ultrashort laser pulses in the visible spectrum must overcome a fundamental difficulty—red light travels faster than blue light through transparent materials like glass. So, when an ultrashort laser pulse passes through a glass lens, the tightly packed wavelengths of light separate, destroying the usefulness of the beam.

This chromatic dispersion problem has plagued optical researchers for decades. Today, most solutions involve additional components that increase the size and bulk of optical devices.

Now, researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have developed a silicon coating that, when applied to the surface of a glass lens, can counteract the effects of dispersion.

The research is published in Nature Communications.

"Our flexible approach can be rapidly implemented in conventional optics and optical setups and be adapted to different spectral regions and applications," said Federico Capasso, the Robert Wallace Professor of Applied Physics and Vinton Hayes Senior Research Fellow in Electrical Engineering at SEAS and senior author of the study.

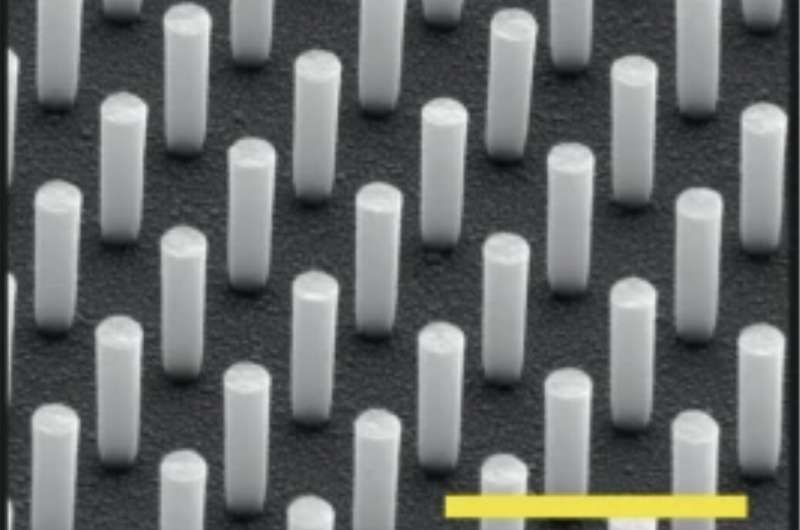

The ultra-thin coating uses precisely designed silicon pillars that briefly capture and hold red light before re-emitting it. This temporary hold allows the slower-moving blue light to catch up.

"Our coating counteracts the dispersive effects of transparent materials, acting as a speed bump for red light and averaging out the speed of each wavelength of light," said Marcus Ossiander, a postdoctoral research fellow at SEAS and first author of the paper.

The researchers tested the coating by shortening laser pulses to only a couple quadrillionths of a second. The nanopillar silicon coating was made using the same commercial lithography tools as industrial semiconductors, making it easy to quickly apply these coatings to existing optical components and expand the applicability of femtosecond laser pulses.

"Now, anyone can buy a lens, put the coating on and use the lens without worrying about dispersion," said Ossiander. "This approach can be the basis for an array of anti- or non-dispersive optics."

More information: Ahmed H. Dorrah et al, Structuring total angular momentum of light along the propagation direction with polarization-controlled meta-optics, Nature Communications (2021). DOI: 10.1038/s41467-021-26253-4

Journal information: Nature Communications