Nondestructive testing of optical fiber diameters

The increased use of optical fiber has seen a greater focus on the precise control and measurement of its diameter. That is due to the diameter being vital for a wide range of fields, from high-speed optical communication to ultra-high sensitivity sensing. Handling optical fiber before measurement can damage the fiber permanently, particularly when multiple-point measurements are needed.

In a new paper published in Light: Advanced Manufacturing, a team of scientists led by Professor Yongkang Dong from the National Key Laboratory of Science and Technology on Tunable Laser at Harbin Institute of Technology has developed a unique technology that measures the mechanical properties of optical fibers through forward stimulated Brillouin scattering (FSBS). The paper, entitled "Non-destructive and distributed measurement of optical fiber diameter with nanometer resolution based on coherent forward stimulated Brillouin scattering," sought to protect optical fiber during the measurement of the diameter so that it can be implemented in the appropriate field.

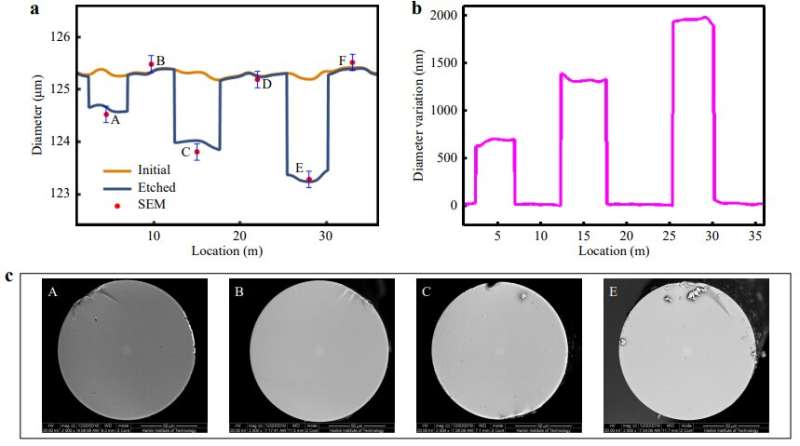

In the past, scanning electron microscopes (SEMs) or optical microscopes are widely employed in many industries for imaging the cross-sections of fibers for measuring fiber diameter. However, optical and electron microscopy is useful only for point measurements. This measurement methodology is destructive as the fiber must be cut at the measurement locations, causing irreversible damage. These conventional microscopy techniques involve a trade-off between the resolution and the microscope's field of view (FOV), limiting resolution to approximately 100 nm for fiber diameters of roughly 125 μm.

FSBS is a nonlinear optomechanical interaction between optical field components and acoustic waves that propagate in a shared medium. In this case, the process occurs in the forward direction with the optical tones either co- or counter-propagating. It was first applied to monitor single-mode fiber diameters in 1992. Under the paradigm, the research team introduced a novel optomechanical protocol called optomechanical time-domain analysis (OMTDA). They can measure the diameter of every part of an optical fiber up to several kilometers. At the same time, it achieved a significantly greater spatial resolution across the optical fiber axis.

What does this mean? In practical terms, it means a more straightforward and non-destructive method of checking optical fiber diameter, with an accuracy of a few nanometers. While this may seem obtuse, the opportunities for science are immense.

More information: Zijie Hua et al, Non-destructive and distributed measurement of optical fiber diameter with nanometer resolution based on coherent forward stimulated Brillouin scattering, Light: Advanced Manufacturing (2021). DOI: 10.37188/lam.2021.025

Provided by Chinese Academy of Sciences