Tube-in-tube structure going strong

Similar to grass stems, Lawrence Livermore National Laboratory (LLNL) scientists have created nanostrut-connected tube-in-tubes that enable stronger low-density structural materials.

Porous materials with engineered stretching-dominated lattice designs, which offer attractive mechanical properties with ultra-light weight and large surface area for wide-ranging applications, have recently achieved near-ideal linear scaling between stiffness and density.

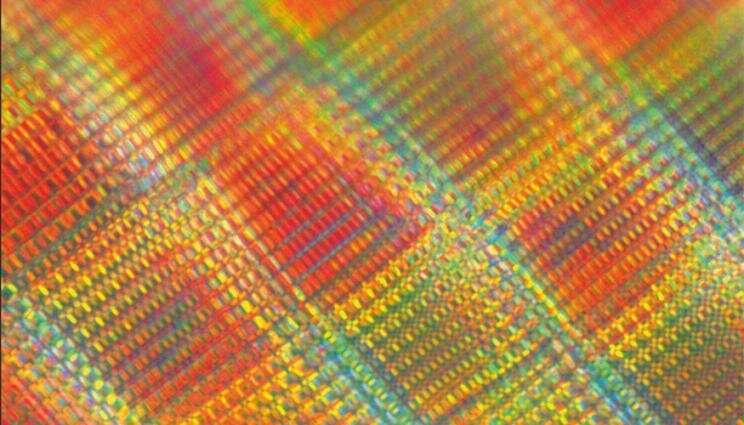

In the new research, the team developed a process to transform fully dense, 3D-printed polymeric beams into graphitic carbon hollow tube-in-tube sandwich structures, where, similar to grass stems, the inner and outer tubes are connected through a network of struts. The research is on the cover of the Oct. 25 issue of Nature Materials.

Compression tests and computational modeling show that this change in beam morphology dramatically slows down the decrease in stiffness with decreasing density. Compression experiments further demonstrated large deformation recovery after 30 percent to 50 percent compression, leading to high gravimetric energy dissipation properties.

Porous ultralow-density materials have many emerging applications, such as mechanical shock absorbers, thermal and acoustic insulation, flexible battery and catalyst scaffolds, MEMS devices and as target materials for high-energy-density physics experiments.

"Some of these applications will benefit from reducing the inactive carbon material density while still providing high specific surface area combined with high stiffness and shape recovery properties," said LLNL material scientist Jianchao Ye, co-lead author of the paper. "Think about batteries or catalysts: the unique tube-in-tube structure combines excellent mechanical properties with low density, and provides large surface area for energy storage or catalysts with facile mass transport pathways."

Similar sandwich panel designs with integrated load-bearing struts also are found in nature, where light weight and good mechanical properties are important. Examples include the skulls of various species, stems of plants and bird bones. While the new strutted tube-in-tube (STinT) carbon structure resembles the architecture of animal skulls and plant stems, its characteristic length scale is orders of magnitude smaller.

To overcome the challenge of rapidly degrading mechanical properties with decreasing density, the team developed the stiff STinT design. Specifically, they fabricated carbon based microlattices with integrated STinT beam morphology through a two-step nickel-catalyzed templating-pyrolysis process. This fabrication process maintains the structure and dimensions of the as-printed sacrificial polymer template to deliver remarkably stiff carbon lattices with densities as low as 6.4 mg/cm3.

"We attribute the stiffness of our low-density carbon lattices to the integrated nanoscale strutted tube-in-tube beam design that enables lightweight but stiff lattice building blocks, a design concept that can be applied orthogonally to current lattice topology optimization efforts," said LLNL material scientist Juergen Biener, a co-author of the paper.

More information: Jianchao Ye et al, Ultra-low-density digitally architected carbon with a strutted tube-in-tube structure, Nature Materials (2021). DOI: 10.1038/s41563-021-01125-w

Journal information: Nature Materials

Provided by Lawrence Livermore National Laboratory