Targeting a rapid market breakthrough for new vaccine production method

In a so-called inactivated or killed vaccine, the virus particles it contains are first rendered inactive by means of the toxic chemical formaldehyde. A better way of achieving this, however, is to irradiate the pathogens with low-energy electrons. Four Fraunhofer Institutes have now developed a new method of vaccine production based on this technique that is not only quicker but also guarantees a higher quality of product. The next step is to take this patented technique to market as quickly as possible. In order to accelerate the transfer and ensure that this new method is truly competitive, the Fraunhofer Institute for Manufacturing Engineering and Automation IPA has teamed up with specialized machinery manufacturer KyooBe Tech GmbH and with TIM Consulting.

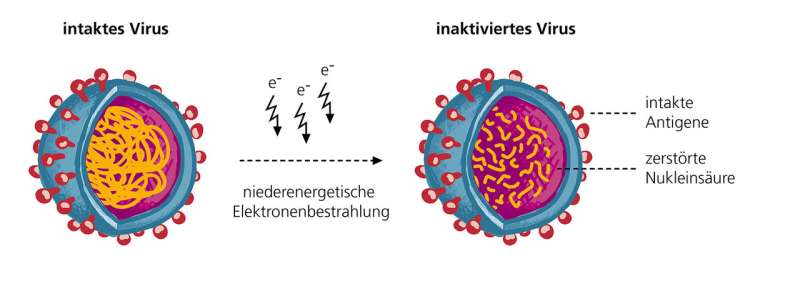

When it comes to diseases such as polio, influenza and hepatitis A, it only takes a small prick of a needle to eliminate these pathogens. Most vaccinations involve the use of inactivated vaccines—i.e., those consisting of virus particles that have already been killed. At present, chemicals are used to eliminate these pathogens—as a rule, the toxic substance formaldehyde. In a project led by the Fraunhofer Institute for Cell Therapy and Immunology IZI, the Fraunhofer Institute for Manufacturing Engineering and Automation IPA has joined forces with the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP and the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB in order to develop a new chemical-free method for producing inactivated vaccines. This uses low-energy electron irradiation to inactivate pathogens in a process that is fast and reproducible. Low-energy electrons destroy the nucleic acid with-in the pathogens and bacteria, while leaving the surface proteins intact. In other words, the parts of the pathogen that provoke the desired response in our immune system remain unaffected by the irradiation. As a result, it will become faster, safer and cheaper to produce vaccines.

A pilot plant for the production of inactivated vaccines has been installed at Fraunhofer IZI in Leipzig. This will serve to scale up this innovative process from the laboratory to the industrial scale, as the prototype is unsuitable for commercial use in pharmaceutical production. In preparation for a successful market launch, a number of technical im-provements are required—along with a sound strategy and business analysis. In this regard, Stuttgart-based Fraunhofer IPA has been able to secure, on behalf of the Fraunhofer-Gesellschaft, the cooperation of two companies, KyooBe Tech GmbH and TIM Consulting. As a spin-off from Bausch+Ströbel Maschinenfabrik Ilshofen, KyooBe Tech can tap into more than 50 years of technological expertise in the production of specialist machinery for the pharmaceutical industry. "For use in industrial vaccine production, the plant will have to be scaled down to the size of a refrigerator," explains Mario Bott, managing director of KyooBe Tech GmbH and a former researcher at Fraunhofer IPA. "At present, we're able to produce four liters of vaccine an hour, but we're working to improve this." The process is also suitable for applications other than vaccine production. For example, it could be used to sterilize biopharmaceuticals and other liquid biological materials. In its development of new production technology for the pharmaceutical industry, the company adopts what it calls an interdisciplinary, proactive, user-centric and holistic approach.

Advance risk-management analysis based on big data

To ensure a smooth transfer of this technology, extensive market research is required. As Martin Thoma explains, various questions have to be addressed: "How will the vaccine market develop in the coming years? Is the patent robust enough? Are other companies working on similar processes? And are there already patents along these lines?" Thoma, deputy head of the department for laboratory automation and biomanufacturing engineering at Fraunhoher IPA, is project lead at the institute.

TIM Consulting has been called in to answer these questions. The company uses a so-phisticated method of market analysis based on big data, which it calls Deep Dive. TIM Consulting was set up by former Fraunhofer IPA researcher Dr. Thomas Abele. Deep Dive reveals development risks and ways of mitigating these. A special software combs through scientific and patent databases so as to condense large volumes of data and discover correlations between different topics. "We use a software called Netculator to identify clearly definable areas of activity related to specific technologies or applica-tions," Abele explains. "These are what we call research fronts." This big data tool uses a hybrid algorithm to detect similarities between documents on the basis of key-words found in them. As a special feature, the software will also generate a timeline showing the chronological development of a specific topic. This serves to identify emerging topics ("white spots") and to register shifting priorities within individual topics. Selected clusters are further broken down into project phases lasting two weeks. For each of these clusters/subclusters, the software identifies experts, companies and institutions active in this field, as well as key publications and patents. This big data analysis is suitable not only for applications in the pharmaceutical industry but also for processes and technologies in other sectors such as the automotive and mechanical engineering industries.

Provided by Fraunhofer-Gesellschaft