July 19, 2017 report

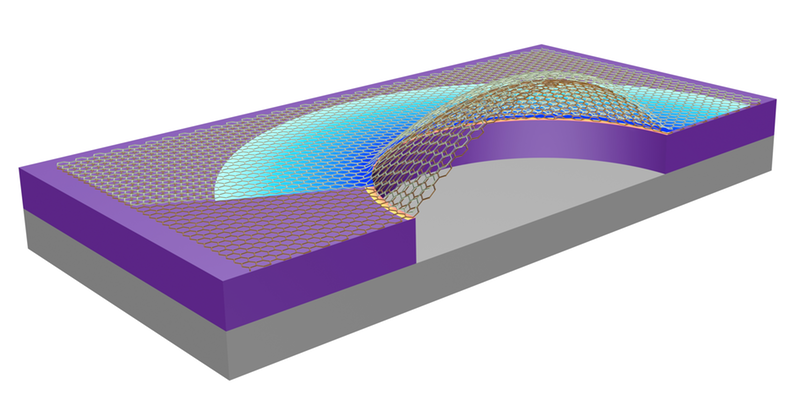

Bubble technique used to measure shear forces between graphene sheets

(Phys.org)—A team of researchers from China and the U.S. has devised a relatively simple means for measuring the shear forces that exist between sheets of graphene and other materials. In their paper published in the journal Physical Review Letters, the group describes the technique and the results they found when using it to measure shear forces for several types of 2-D materials.

As graphene sheets are used in more applications, it has become important to better understand the shear forces at play between them and other materials. Learning more could prevent sheets from coming apart, for example, when they are used to make an electronic device. In some applications, graphene sheets are layered with other graphene sheets, while in others, graphene sheets are applied to sheets of other materials. But until now, there was no way to measure how well such materials clung to one another. Traditionally, such measurements are made by adhering sheets of material and then pulling them in opposite directions—a means of measuring their shear force. But because graphene sheets are single atom thick, that approach is not feasible. In this new effort, the researchers have found a new way to measure shear forces between such materials.

In the new method, tiny holes were drilled in one sheet before it was adhered to another sheet. Air was then used to generate pressure from below, causing the top sheet to rise and pulling the sheet below with it, forming a bubble. The researchers then used Raman spectroscopy to measure the amount of stretching at the base of the bubble as a means of measuring the shear forces between the two materials.

Using their technique, the researchers were able to measure the shear force between two sheets of graphene and found it to be 40 kPa, which is considered very small and unsurprising, as sheets of graphene have been used as a lubricant. The team also measured the shear force between a sheet of graphene and a sheet of silicon dioxide, and found it to be 1.64 MPa—which is approximately 40 times greater than the shear force between graphene sheets.

More information: Guorui Wang et al. Measuring Interlayer Shear Stress in Bilayer Graphene, Physical Review Letters (2017). DOI: 10.1103/PhysRevLett.119.036101

ABSTRACT

Monolayer two-dimensional (2D) crystals exhibit a host of intriguing properties, but the most exciting applications may come from stacking them into multilayer structures. Interlayer and interfacial shear interactions could play a crucial role in the performance and reliability of these applications, but little is known about the key parameters controlling shear deformation across the layers and interfaces between 2D materials. Herein, we report the first measurement of the interlayer shear stress of bilayer graphene based on pressurized microscale bubble loading devices. We demonstrate continuous growth of an interlayer shear zone outside the bubble edge and extract an interlayer shear stress of 40 kPa based on a membrane analysis for bilayer graphene bubbles. Meanwhile, a much higher interfacial shear stress of 1.64 MPa was determined for monolayer graphene on a silicon oxide substrate. Our results not only provide insights into the interfacial shear responses of the thinnest structures possible, but also establish an experimental method for characterizing the fundamental interlayer shear properties of the emerging 2D materials for potential applications in multilayer systems.

Journal information: Physical Review Letters

© 2017 Phys.org