Wonder material? Novel nanotube structure strengthens thin films for flexible electronics

Reflecting the structure of composites found in nature and the ancient world, researchers at the University of Illinois at Urbana-Champaign have synthesized thin carbon nanotube (CNT) textiles that exhibit both high electrical conductivity and a level of toughness that is about fifty times higher than copper films, currently used in electronics.

"The structural robustness of thin metal films has significant importance for the reliable operation of smart skin and flexible electronics including biological and structural health monitoring sensors," explained Sameh Tawfick, an assistant professor of mechanical science and engineering at Illinois. "Aligned carbon nanotube sheets are suitable for a wide range of application spanning the micro- to the macro-scales including Micro-Electro-Mechanical Systems (MEMS), supercapacitor electrodes, electrical cables, artificial muscles, and multi-functional composites.

"To our knowledge, this is the first study to apply the principles of fracture mechanics to design and study the toughness nano-architectured CNT textiles. The theoretical framework of fracture mechanics is shown to be very robust for a variety of linear and non-linear materials."

Carbon nanotubes, which have been around since the early nineties, have been hailed as a "wonder material" for numerous nanotechnology applications, and rightly so. These tiny cylindrical structures made from wrapped graphene sheets have diameter of a few nanometers—about 1000 times thinner than a human hair, yet, a single carbon nanotube is stronger than steel and carbon fibers, more conductive than copper, and lighter than aluminum.

However, it has proven really difficult to construct materials, such as fabrics or films that demonstrate these properties on centimeter or meter scales. The challenge stems from the difficulty of assembling and weaving CNTs since they are so small, and their geometry is very hard to control.

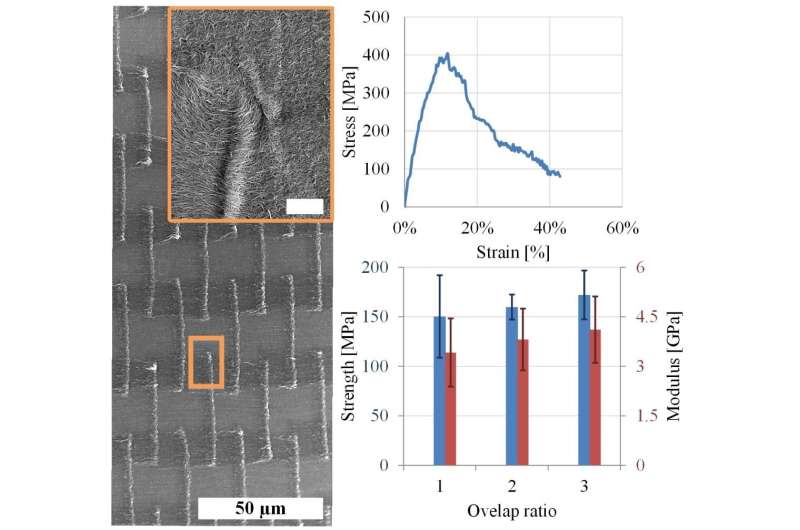

"The study of the fracture energy of CNT textiles led us to design these extremely tough films," stated Yue Liang, a former graduate student with the Kinetic Materials Research group and lead author of the paper, "Tough Nano-Architectured Conductive Textile Made by Capillary Splicing of Carbon Nanotubes," appearing in Advanced Engineering Materials. To our knowledge, this is the first study of the fracture energy of CNT textiles.

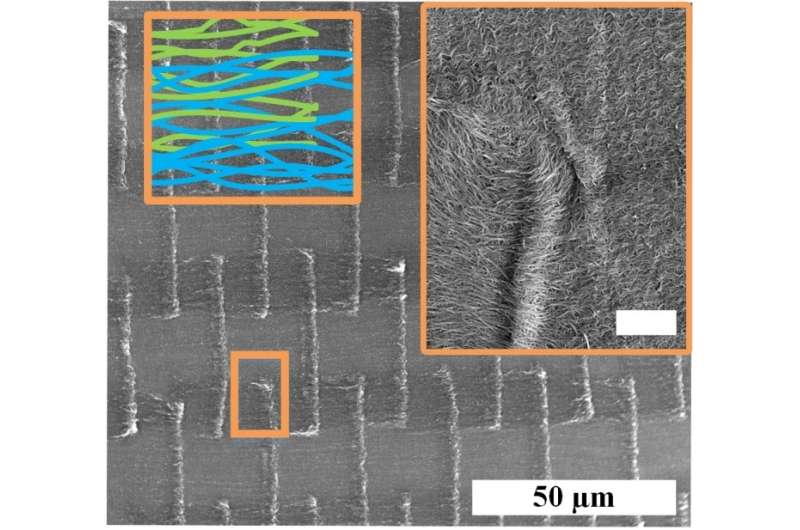

Beginning with catalyst deposited on a silicon oxide substrate, vertically aligned carbon nanotubes were synthesized via chemical vapor deposition in the form of parallel lines of 5?μm width, 10?μm length, and 20-60?μm heights.

"The staggered catalyst pattern is inspired by the brick and mortar design motif commonly seen in tough natural materials such as bone, nacre, the glass sea sponge, and bamboo," Liang added. "Looking for ways to staple the CNTs together, we were inspired by the splicing process developed by ancient Egyptians 5,000 years ago to make linen textiles. We tried several mechanical approaches including micro-rolling and simple mechanical compression to simultaneously re-orient the nanotubes, then, finally, we used the self-driven capillary forces to staple the CNTs together."

"This work combines careful synthesis, and delicate experimentation and modeling," Tawfick said. "Flexible electronics are subject to repeated bending and stretching, which could cause their mechanical failure. This new CNT textile, with simple flexible encapsulation in an elastomer matrix, can be used in smart textiles, smart skins, and a variety of flexible electronics. Owing to their extremely high toughness, they represent an attractive material, which can replace thin metal films to enhance device reliability."

In addition to Liang and Tawfick, co-authors include David Sias and Ping Ju Chen.

More information: Yue Liang et al, Tough Nano-Architectured Conductive Textile Made by Capillary Splicing of Carbon Nanotubes , Advanced Engineering Materials (2017). DOI: 10.1002/adem.201600845

Provided by University of Illinois at Urbana-Champaign