Researchers use microwaves to produce high-quality graphene

Rutgers University engineers have found a simple method for producing high-quality graphene that can be used in next-generation electronic and energy devices: bake the compound in a microwave oven.

The discovery is documented in a study published online today in the journal Science.

"This is a major advance in the graphene field," said Manish Chhowalla, professor and associate chair in the Department of Materials Science and Engineering in Rutgers' School of Engineering. "This simple microwave treatment leads to exceptionally high quality graphene with properties approaching those in pristine graphene."

The discovery was made by post-doctoral associates and undergraduate students in the department, said Chhowalla, who is also the director of the Rutgers Institute for Advanced Materials, Devices and Nanotechnology. Having undergraduates as co-authors of a Science paper is rare but he said "the Rutgers Materials Science and Engineering Department and the School of Engineering at Rutgers cultivate a culture of curiosity driven research in students with fresh ideas who are not afraid to try something new.''

Graphene - 100 times tougher than steel - conducts electricity better than copper and rapidly dissipates heat, making it useful for many applications. Large-scale production of graphene is necessary for applications such as printable electronics, electrodes for batteries and catalysts for fuel cells.

Graphene comes from graphite, a carbon-based material used by generations of students and teachers in the form of pencils. Graphite consists of sheets or layers of graphene.

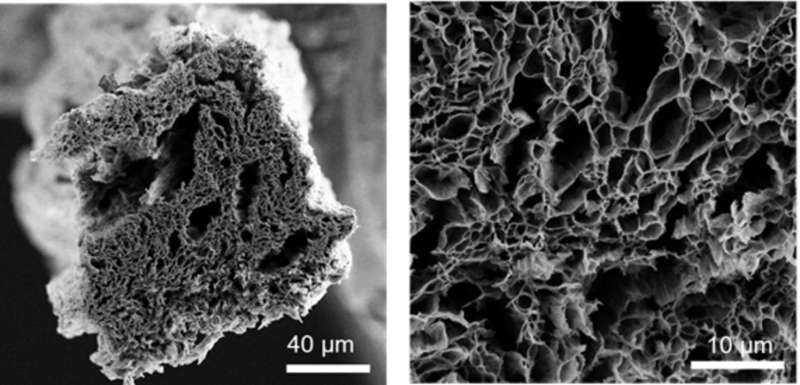

The easiest way to make large quantities of graphene is to exfoliate graphite into individual graphene sheets by using chemicals. The downside of this approach is that side reactions occur with oxygen - forming graphene oxide that is electrically non-conducting, which makes it less useful for products.

Removing oxygen from graphene oxide to obtain high-quality graphene has been a major challenge over the past two decades for the scientific community working on graphene. Oxygen distorts the pristine atomic structure of graphene and degrades its properties.

Chhowalla and his group members found that baking the exfoliated graphene oxide for just one second in a 1,000-watt microwave oven, like those used in households across America, can eliminate virtually all of the oxygen from graphene oxide.

More information: "High-quality graphene via microwave reduction of solution-exfoliated graphene oxide," Science, science.sciencemag.org/lookup/ … 1126/science.aah3398

Journal information: Science

Provided by Rutgers University