Materials scientists take big step toward tougher ductile ceramics

A team of materials scientists at the UCLA Henry Samueli School of Engineering and Applied Science is exploring ways to create tough ceramics, a long sought-after class of materials that would be exceptionally hard, capable of withstanding extremely high temperatures and less prone to corrosion than metals, but still have the ability to become dented or deformed without fracturing—a property called ductility. In other words, a ceramic that bends but doesn't break.

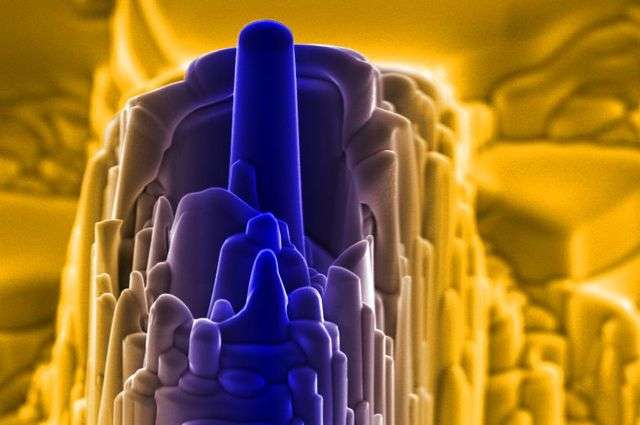

The researchers focused on compounds called transition-metal carbides whose atoms are held together by three types of chemical bonds—ionic, covalent and metallic. The combination of the three bonds, researchers believe, is what makes these materials tough. To validate that hypothesis, the team performed compression tests on single crystals of two transition-metal carbides, zirconium carbide and tantalum carbide, inside a transmission electron microscope.

They observed that the crystals deformed—that is, they changed shape without cracking—at room temperature. This showed that the crystals' size and orientation play an important role in the materials' mechanical behavior.

"Ultra–high-temperature ceramics are highly desirable in aerospace and other industries where durable structural components are required to maintain their strength and stability at elevated temperatures," said Suneel Kodambaka, associate professor of materials science and engineering. "Transition-metal carbides are attractive for these applications because they are very hard and do not melt until they reach very high temperatures."

Materials scientists use the term "hardness" as a measure of a material's resistance to mechanical pressure, and the property can be measured in units called Pascals. The hardness of transition-metal carbides exceeds 20 gigapascals; in comparison, steel measures about 1 to 2 gigapascals. And transition-metal carbides melt at temperatures above 6,300 degrees Fahrenheit; steels generally melt at around 2,700 degrees Fahrenheit.

"Despite these favorable qualities, these ceramics are more brittle compared to steels at room temperature," Kodambaka said. "Our studies showed how their crystals slip, an atomic-scale process that controls malleability, at room temperature. These results could help engineer the microstructures of ceramic components to tailor their mechanical properties."

Today, high-strength metallic alloys are generally preferred to ceramics in machinery like aircraft engines and turbines and in and structural applications like nuclear power plants. Using ductile ceramics would significantly boost the components' performance and durability. The researchers also suggest that the new ceramics hold promise for use in miniature mechanical components, for example in micro- and nano-electromechanical systems, and flexible-yet-strong and radiation-resistant foils for use in solar sails, which are used to propel spacecraft.

According to the study, ductile ceramics could be developed based on transition-metal carbides and possibly transition-metal nitrides, which have similar structures. Additional research is needed to understand the atomic-scale mechanisms that affect plasticity in these materials.

The research was published as an invited feature article in the Journal of the American Ceramics Society.

More information: "Nanomechanics of Refractory Transition-Metal Carbides: A Path to Discovering Plasticity in Hard Ceramics." Journal of the American Ceramic Society August 2015 DOI: 10.1111/jace.13686

Journal information: Journal of the American Ceramic Society

Provided by University of California, Los Angeles