MEMS sensors and platforms to build a hyper-attentive world of objects

Ever wonder how your smartphone got so smart? It stores pictures right-side up, knows where the North Star is, and always brings you home. This spatial acumen originates from micrometer-sized devices known as microelectromechanical systems (MEMS) that sense velocity, acceleration and magnetic field strength. Demand for MEMS has boomed recently, with MEMS sensors finding their way into satellites, cars, gaming consoles, cameras and, of course, mobile phones.

"MEMS technology is re-invigorating the somewhat stagnant semiconductor industry," says Alex Gu, director of the Sensors, Actuators and Microsystems Programme at the A*STAR Institute of Microelectronics (IME). "Produced using the same set of tools and processes as the conventional semiconductor industry, MEMS support the integration of multiple sensing functionalities onto a very small footprint at a very affordable price." MEMS facilitate the intercommunication of objects envisioned by 'the Internet of things', where light bulbs connect with smartphones and traffic lights with approaching vehicles.

Gu and colleagues at IME are realizing this vision through developing advanced MEMS devices that monitor the environment, harvest vibrational energy and keep time. They are also contributing to the three-dimensional consolidation of stand-alone MEMS devices onto one shared platform with integrated circuits, paving the way for large-scale deployment.

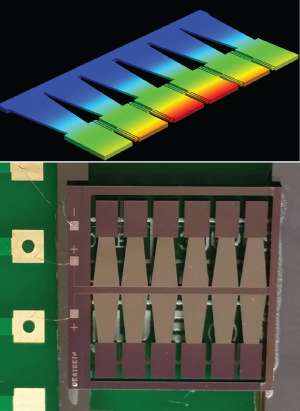

Gases such as carbon dioxide, hydrocarbons and ketones are critical indicators for environmental monitoring. They absorb light at specific wavelengths in the mid-infrared region. Optical detectors read the absorption signatures of gases in the atmosphere but are too bulky, expensive or specialized. Gu's team is developing a MEMS gas-sensing platform that is small enough to fit in a mobile phone and that can be tuned over a wide wavelength range, allowing it to monitor various gases associated with environmental and health risks. Sensor lifetimes, however, are limited by battery capacity—a common problem for wireless sensor nodes. To overcome this issue, MEMS vibration energy harvesters convert otherwise wasted ambient vibrational energy into usable electrical energy to sustain the sensors. IME researchers are expanding the frequency range of existing harvesters to double their efficiency (see image).

Timing devices are essential for synchronizing multiple components in electronic systems and tracking the chronology of events as simple as mouse swerves and clicks. The market is currently dominated by devices based on quartz crystals cut to different sizes and shapes to achieve appropriate frequencies. But time is running out for this technology. Gu's team is developing compact MEMS timing devices that have customizable frequencies and superior performance. Furthermore, they are much cheaper to manufacture than quartz-based devices. "MEMS are fabricated using batch processing techniques. We could produce over 60,000 timing devices on an 8-inch silicon wafer for a few cents per device—quartz-based devices cost two to three times that," says Gu, who expects to have prototypes ready by the end of next year.

Gu's team closely collaborates with Navab Singh's IME MEMS Integration group to develop standardized processes and platforms that can accommodate multiple devices—from an all-in-one gyroscope, accelerometer and magnetometer combo, to added features such as pressure and gas sensors. "We are very serious about system integration," says Singh. "IME's major advantage is that we can design and construct MEMS sensors, test them on integrated circuits and package them—all under one roof." And with the recent linkage between IME and Murata Manufacturing, a Japan-headquartered company specializing in advanced electronic materials and components, industry leaders are clearly sensing IME's strengths.