Nanoribbon film keeps glass ice-free: Team refines deicing film that allows radio frequencies to pass

Rice University scientists who created a deicing film for radar domes have now refined the technology to work as a transparent coating for glass.

The new work by Rice chemist James Tour and his colleagues could keep glass surfaces from windshields to skyscrapers free of ice and fog while retaining their transparency to radio frequencies (RF).

The technology was introduced this month in the American Chemical Society journal Applied Materials and Interfaces.

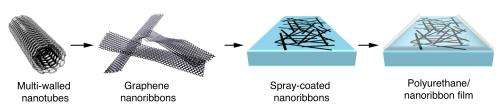

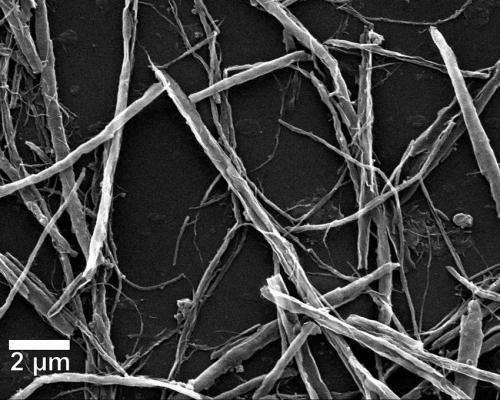

The material is made of graphene nanoribbons, atom-thick strips of carbon created by splitting nanotubes, a process also invented by the Tour lab. Whether sprayed, painted or spin-coated, the ribbons are transparent and conduct both heat and electricity.

Last year the Rice group created films of overlapping nanoribbons and polyurethane paint to melt ice on sensitive military radar domes, which need to be kept clear of ice to keep them at peak performance. The material would replace a bulky and energy-hungry metal oxide framework.

The graphene-infused paint worked well, Tour said, but where it was thickest, it would break down when exposed to high-powered radio signals. "At extremely high RF, the thicker portions were absorbing the signal," he said. "That caused degradation of the film. Those spots got so hot that they burned up."

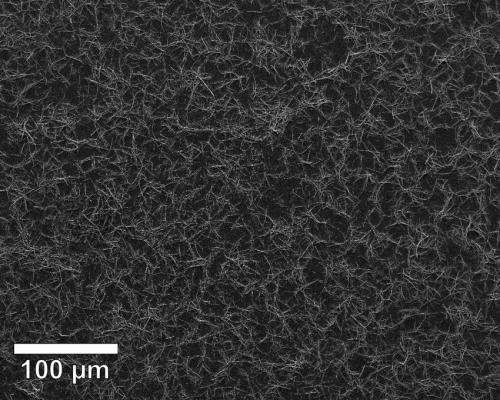

The answer was to make the films more consistent. The new films are between 50 and 200 nanometers thick – a human hair is about 50,000 nanometers thick – and retain their ability to heat when a voltage is applied. The researchers were also able to preserve their transparency. The films are still useful for deicing applications but can be used to coat glass and plastic as well as radar domes and antennas.

In the previous process, the nanoribbons were mixed with polyurethane, but testing showed the graphene nanoribbons themselves formed an active network when applied directly to a surface. They were subsequently coated with a thin layer of polyurethane for protection. Samples were spread onto glass slides that were then iced. When voltage was applied to either side of the slide, the ice melted within minutes even when kept in a minus-20-degree Celsius environment, the researchers reported.

"One can now think of using these films in automobile glass as an invisible deicer, and even in skyscrapers," Tour said. "Glass skyscrapers could be kept free of fog and ice, but also be transparent to radio frequencies. It's really frustrating these days to find yourself in a building where your cellphone doesn't work. This could help alleviate that problem."

Tour noted future generations of long-range Wi-Fi may also benefit. "It's going to be important, as Wi-Fi becomes more ubiquitous, especially in cities. Signals can't get through anything that's metallic in nature, but these layers are so thin they won't have any trouble penetrating."

He said nanoribbon films also open a path toward embedding electronic circuits in glass that are both optically and RF transparent.

More information: Applied Materials and Interfaces, pubs.acs.org/doi/abs/10.1021/am503478w

Journal information: ACS Applied Materials and Interfaces

Provided by Rice University