Simple sewing machine has high-tech role in future 'soft' machines

The humble sewing machine could play a key role in creating "soft" robotics, wearable electronics and implantable medical systems made of elastic materials that are capable of extreme stretching.

New stretchable technologies could lead to innovations including robots that have humanlike sensory skin and synthetic muscles and flexible garments that people might wear to interact with computers or for therapeutic purposes.

"However, you would need a low-cost, highly stretchable electrical conductor to interconnect sensors and other components in these applications," said Babak Ziaie, a Purdue University professor in the School of Electrical and Computer Engineering and Weldon School of Biomedical Engineering.

Other researchers are pursuing approaches that require the use of complicated and expensive microfabrication techniques or exotic technologies such as liquid-metal-filled microchannels and ultrathin wires prone to breaking.

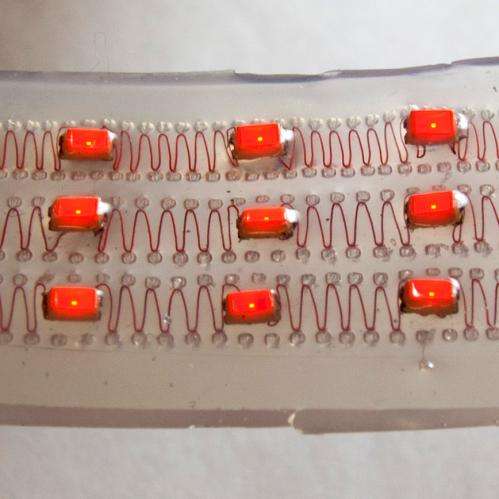

Now, a Purdue team has come up with a far simpler, less-costly alternative: Use a standard sewing machine to create ultra-stretchable interconnects out of conventional wire. The wire is sewn in a zigzag pattern and embedded in a rubbery, stretchable "elastomer" called Ecoflex, manufactured by Smooth-On Inc.

The researchers have demonstrated that the interconnect is capable of stretching 500 percent of its length.

"This compares to only a few percent for an ordinary metal connection," said Ziaie, leading the research with doctoral student Rahim Rahimi. "The structures are also highly robust, capable of withstanding thousands of repeated stretch-and-release cycles."

Findings are detailed in a paper being presented during the Solid-State Sensors, Actuators and Microsystems Workshop on June 8-12 in Hilton Head Island, S.C. The paper was authored by Rahimi, Ziaie, and doctoral students Manuel Ochoa and Wuyang Yu.

Since it was not practical to sew the wire directly into the rubbery elastomer because of its squishy nature, the researchers developed a technique to first sew the wire into a sheet of polyethylene terephthalate (PET), the same material used to make transparencies for overheard projectors. The zigzag wire pattern was stitched to the PET sheets with a water-soluble thread. Then the rubbery stretchable polymer was poured over the sheet, encasing the wire as it solidified. Warm water was used to dissolve the thread, and the flexible polymer was separated from the PET sheet with the wire embedded in it.

The researchers used their technique to demonstrate a stretchable "inductive strain sensor" for monitoring expansion of an inflatable urinary catheter balloon. Strain gauges measure how much a material stretches or deforms. Because conventional strain gauges are made of rigid metal film, they can't measure more than a small percentage of the deformation before breaking, whereas a soft strain gauge could continue stretching with the material.

More information: "A sewing-enabled stitch-and-transfer method for robust, ultra-stretchable, conductive interconnects." Rahim Rahimi, Manuel Ochoa, Wuyang Yu, and Babak Ziaie. Presentation to Solid-State Sensors, Actuators and Microsystems Workshop. Purdue University.

ABSTRACT

Fabricating highly stretchable and robust electrical interconnects at low-cost remains an unmet challenge in stretchable electronics. Previously reported stretchable interconnects require complicated fabrication processes that result in devices with limited stretchability, poor reliability, and large gauge factors. Here, we demonstrate a novel sew-and-transfer method for rapid fabrication of low-cost, highly-stretchable interconnects. A zigzag pattern of thin metal wires is sewn into a polymeric film using a commercial sewing machine and a double-thread stitch, where one of the threads is water-soluble polyvinyl alcohol (PVA). The pattern is subsequently transferred onto a stretchable elastomeric substrate by dissolving the PVA in warm water. The resulting structures exhibit extreme stretchability exceeding 500 % strain for a zigzag angle of 18°. They are also highly robust, capable of withstanding thousands of repeated stretch-and-release cycles (18,000 at 110 % strain, 50,000 at 55 % strain, and >120,000 at 30 % strain) without any noticeable change in resistance even at maximum strain levels. Using this technique, we demonstrate a stretchable inductive strain sensor for monitoring balloon expansion in a Foley urinary catheter. The sensor is capable of detecting changes in balloon diameter from 9 mm to 38 mm, with an average sensitivity of 4 nH/mm.

Provided by Purdue University