Mobile PCB cleanup system developed

University of Calgary scientists have developed new technology that promises a safer, cheaper way to clean up hazardous PCBs in soil using ultraviolet light – the first technology of its kind in the world.

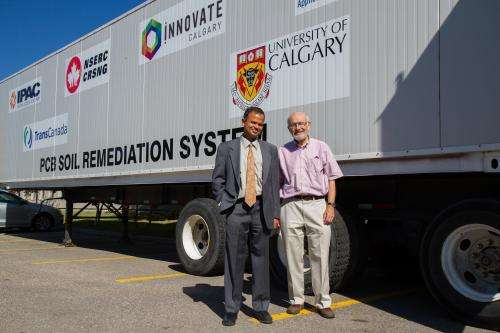

The university research team, in collaboration with TransCanada Corp., Innovate Calgary, SAIT Polytechnic and IPAC Services Corp., created a 15-metre-long, mobile cleanup unit that is ready for field-testing on PCB-contaminated soil.

The $1-million, 13-year research and development project – with significant funding from the Natural Sciences and Engineering Research Council of Canada – promises to provide industry with a safer, more convenient and much less costly way of remediating thousands of tonnes of PCBs still in the environment.

"We are confident this technology will work. We've established the process, tested it successfully in the laboratory and published many scientific papers," says Gopal Achari, professor of civil engineering in the Schulich School of Engineering's Centre for Environmental Engineering Research and Education.

"The pilot, mobile cleanup unit is designed to get this technology into the hands of a company that can bring it forward into regular, widespread use," says Cooper Langford, professor of chemistry in the Faculty of Science, and an internationally recognized expert in photochemistry.

Globally, millions of tonnes of PCBs, or polychlorinated biphenyls, were produced and used in hundreds of industrial and commercial applications before being banned in 1979. Research showed the toxic organic chemical compounds could enter the food chain and potentially cause reproductive and developmental damage as well as cancer.

Spills, legal and illegal disposal, and uncontrolled use prior to 1979 resulted in an estimated one-third of the total U.S. production of 635,000 tonnes being released into the North American environment.

Currently, the most common way to dispose of PCBs in soil in Canada is to dig up the contaminated soil and transport it to either the Swan Hills hazardous waste treatment plant in Alberta or a similar facility in Quebec, where the PCBs are destroyed in specialized high-temperature incinerators. In addition to potential health and safety risks associated with removing and transporting contaminated soil, this disposal method is expensive, costing as much as $1,000 per tonne of soil.

With the University of Calgary's new technology, the PCB-contaminated soil can be cleaned onsite – eliminating the need for transportation – and put back in the same place. The researchers estimate the cost to use their system, once brought to commercial scale, will be about $350 to $500 per tonne – one-third to one-half the cost of soil excavation, transportation and incineration.

Innovate Calgary, the university's technology transfer office, managed the overall project and the patenting in Canada of the new technology.

"We're now looking for any partners that would like to use the mobile cleanup unit, which is very practical for small PCB spills in soil," says Jim Wilson, Innovate Calgary's licensing manager, health and environmental technology.

TransCanada invested approximately $500,000 to develop the technology and will take part in testing it as part of the company's ongoing efforts to reduce health, safety and environmental risks.

"This is a contribution we can make to help companies in any industry – utilities, pipelines oil and gas – address sites potentially impacted by PCBs," says Darion Byerley, environmental specialist in the company's civil and environmental engineering team.

At SAIT Polytechnic's Applied Research and Innovation Services department, the Environmental Technologies research group took the University of Calgary researchers' concept and turned it into a larger, pilot-scale working system, housed in a 15-metre-long shipping container. SAIT made cash and in-kind investments into the PCB soil remediation pilot that combines several complex technologies and is rated to treat one cubic metre of PCB-impacted soil per day.

"This project represents the best of collaboration between the University of Calgary's fundamental research and SAIT's applied research, to find a useful and timely solution to a 'real-world' problem," says Vita Martez, senior research associate of Environmental Technologies at SAIT.

The pilot mobile cleanup unit is capable of removing, in a few treatment cycles, most of the PCBs from soil and then degrading them in a photoreactor using germicidal (UV) lamps. The pilot can treat up to one cubic metre of soil per day. A commercial-sized unit – installed in three tractor-trailers, for example – could triple that capacity, the researchers say.

Provided by University of Calgary