NIST shows how to make a compact frequency comb in minutes

Laser frequency combs-high-precision tools for measuring different colors of light in an ever-growing range of applications such as advanced atomic clocks, medical diagnostics and astronomy-are not only getting smaller but also much easier to make.

Physicists at the National Institute of Standards and Technology (NIST) can now make the core of a miniature frequency comb in one minute. Conventional microfabrication techniques, by contrast, may require hours, days or even weeks.

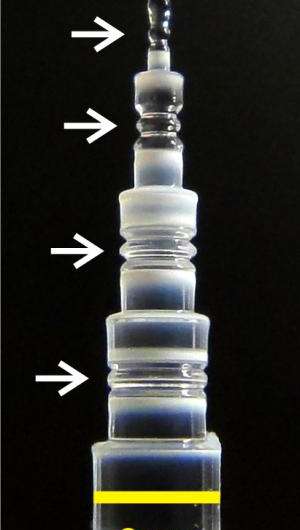

The NIST technique involves laser machining of a quartz rod (a common type of glass) to shape and polish a small, smooth disk within which light can circulate (see video clip). The user controls the size and shape of this optical cavity, or resonator. Its diameter can be varied from about one-fifth of a millimeter to 8 millimeters, and its thickness and curvature can be shaped as well. The quality factor-Q factor, which is a measure of the length of time light circulates inside the cavity without leaking out-equals or exceeds that of cavities made by other methods.

After machining the quartz, NIST scientists use a small, low-power infrared laser to pump light into it. A primary benefit of the high Q factor is that only a few milliwatts of laser light are required to generate a comb.

"We make a resonator in one minute, and one minute after that we are making a frequency comb," NIST researcher Scott Papp says.

View a brief video of the laser machining technique with Scott Papp:

NIST's one-minute method is simple and far less expensive than conventional microfabrication. The system for the NIST process costs about $10,000-most of that for purchase of a carbon dioxide laser used for cutting-compared to between $1 million and $10 million for a microfabrication system that must be used in a cleanroom.

A full-size frequency comb uses high-power, ultrafast lasers and is generally the size of a small table. NIST researchers have been making compact frequency combs for several years and often make cavities out of bulk fused quartz, an inexpensive glass material.

By confining light in a small space, the optical cavity-which, confusingly enough, is solid-enhances optical intensity and interactions. The comb itself is the light, which starts out as a single color or frequency that through optical processes is transformed to a set of additional shades, each sharply defined and equally spaced on the spectrum. A typical NIST microcomb might have 300 "teeth," or ticks on the ruler, each a slightly different color. A key advantage of microcombs is the ability to tune the spacing between the teeth, as needed, for applications such as calibrating astronomical instruments. The spacing is determined by the size of the cavity; a smaller cavity results in wider spacing between the comb teeth.

Scientists plan to apply for a patent on the machining technique, which could be applied to a variety of other glassy materials. Future NIST research will focus on continuing improvements in comb performance and use of the resonators in other compact applications such as optical frequency standards and low-noise microwave oscillators.

More information: S.B. Papp, P. Del'Haye and S.A. Diddams. 2013. Mechanical control of a microrod-resonator optical frequency comb. Physical Review X. 3, 031003 (2013). DOI: 10.1103/PhysRevX.3.031003. Published online July 8, 2013.

P. Del'Haye, S.A. Diddams and S.B. Papp. 2013. Laser-Machined Ultra-High-Q Microrod Resonators for Nonlinear Optics. Applied Physics Letters. Posted online June 7, 2013.

Journal information: Physical Review X , Applied Physics Letters

Provided by National Institute of Standards and Technology