DARPA seeks non-thermal approaches to thin-film deposition

When the Department of Defense (DoD) wants to build a jet engine, it doesn’t put a team of engineers in a hangar with a block of metal and some chisels. Jet engines are made up of individual components that are carefully assembled into a finished product that possesses the desired performance capabilities. In the case of thin-film deposition—a process in which coatings with special properties are bonded to materials and parts to enhance performance—current science addresses the process as though it is attempting to build a jet engine from a block of metal, focusing on the whole and ignoring the parts. Like a jet engine, the thin-film deposition process could work better if it was addressed at the component level.

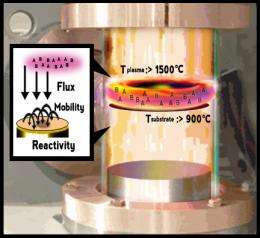

Thin-film deposition requires high levels of energy to achieve the individual chemical steps to deposit a coating on a substrate. Under the current state of practice, that necessary energy is generated by applying very high temperatures—more than 900 degrees Celsius in some cases—at the surface of the substrate as part of a chemical vapor deposition process. The problem with using the thermal energy hammer is that the minimum required processing temperatures exceed the maximum temperatures that many substrates of interest to DoD can withstand. As a result, a wide range of capabilities remain out of reach.

DARPA created the Local Control of Materials Synthesis (LoCo) program to overcome the reliance on high thermal energy input by addressing the process of thin-film deposition at the component level in areas such as reactant flux, surface mobility, reaction energy, nucleation and by-product removal, among others. In so doing, LoCo will attempt to create new, low-temperature deposition processes and a new range of coating-substrate pairings for use in DoD technologies.

“What really matters in thin-film deposition is energy, not heat,” said Brian Holloway, DARPA program manager. “If we break down the thin-film deposition process into components, we should be able to achieve better results by looking at each piece individually and then merging those solutions into a new low-temperature process. It’s going to be researchers in specialties like plasma chemistry, photophysics, surface acoustic spectroscopy and solid-state physics who make it possible. DARPA seeks scientists who can contribute pieces of the puzzle so that the LoCo team can put them together.”

Breakthroughs in thin-film deposition could enhance performance and enable new capabilities across a range of DoD technologies, impacting areas as diverse as artificial arteries, corrosion-resistant paint and steel combinations, erosion-resistant rotor blades, photovoltaics and long-wavelength infrared missile domes, among others.

As a second focus area, the LoCo program seeks performers to evaluate the cost and performance impacts of coating application to existing DoD parts and systems. Through these assessments, DARPA hopes to identify a specific piece of equipment that would benefit from a novel coating to use as a test bed for any new thin-film deposition process. Through this parallel effort, LoCo intends to move from initial research to practical application within three years.

Source: DARPA