From silicon to the sea: Managing heat aboard modern ships

With a major grant from the Office of Naval Affairs, researchers at Rensselaer Polytechnic Institute are collaborating with four other universities to address a hot topic in today's military: how to keep modern ships cool in extreme environments.

Led by the University of Virginia and funded under the Department of Defense Multidisciplinary University Research Initiative (MURI) program, the overall research aim will be to develop cooling techniques that can be used for thermal management of large-scale, distributed high-power electronic systems. The project is funded by a $7.5 million grant.

In today's modern warfront, sailors and other military personnel are asked to operate more advanced electronics in hotter climates. Modern military ships, offices, and planes have thousands of computers, lights, and other electronics whirring and working at once, generating extremely high temperatures that require advanced cooling systems.

Because of the increasing power levels of today's electronics, and the need for these systems to operate at super-fast speeds in extreme environments, researchers need to find new cooling methods to lengthen the life of electronics and increase system performance, according to Michael Jensen, professor of mechanical, aerospace, and nuclear engineering and project manager for Rensselaer's part of the project.

The researchers involved in the cross-university collaboration will work to develop thermal management techniques that reduce device temperatures below 50 degrees Celsius. To do this, each of the universities will use their research strengths, handling different research thrusts that will later be integrated to help develop the next generation of ultra-efficient electronic systems.

“We are looking to make fundamental advancements in thermal regulation of electronic systems, from pinky-nail-sized chips to an entire computer server farm at a high-tech company or a 500-foot Navy ship," Jensen said.

Rensselaer will lead the research thrust examining the potential of using liquids to cool electronic systems. They will focus on interactions at the interface between hot electronic circuitry and a liquid, as well as determining how to integrate and manage the cooling of thousands of heat-generating sources distributed over a wide area.

“We are reaching the limit of what we can do with air cooling of new computer chips," Jensen said. “We are now looking at liquid cooling as an alternative method to cool electronic circuitry."

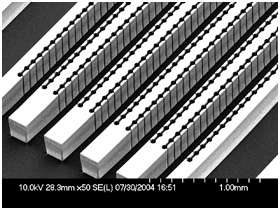

Rensselaer researchers will work to uncover the mechanisms that govern fluid flow and heat transfer in novel electronic cooling systems. As part of that process they will examine the flow and cooling levels of different liquids through micro-devices. This will help them develop modifications to material surface chemistry and structure, understand ideal microchannel configurations and examine the use of nanoparticle suspensions within liquid coolants to improve overall cooling.

Rensselaer also will play a major role in a thrust to design a large-scale thermal system simulator. The simulator will create models of different distributed heat sources and cooling systems and permit researchers to model and control the cooling of a system over time, allowing the military to test cooling techniques prior to implementation.

Source: Rensselaer Polytechnic Institute