February 12, 2007 feature

Handheld windmills serve as electric generators

It’s not quite nanotechnology, but these inches-long windmills can generate small amounts of electric energy to power a variety of low-voltage applications. Since they’re made entirely of plastic, they cost just dollars to manufacture, offering potential for many uses including battery recharging, lighting in remote areas, and wireless sensors.

As a clean, free, and natural option, harnessing wind power for use as a source of energy is appealing, although it’s usually considered on a large scale. Windmill farms with 100s of giant windmills have been built to supply partial power to towns, but wind power can also have simple applications on a small scale. For example, some bicycle lights work by wind power, but the electromagnetic converter they use requires large amounts of mechanical energy, which is not available for most applications.

However, scientists Robert Myers, Mike Vickers, Hyeoungwoo Kim, and Shashank Priya from the University of Texas Arlington have recently investigated other possible designs that might make a small-scale windmill feasible. To convert wind energy into electric energy, they use a piezoelectric structure, where bimorphs (thin plastic sheets) aligned in a row are caused to vibrate via a lever and crankshaft which is attached to the wind vanes.

“Piezoelectrics require a very small magnitude of deflection to generate high voltages,” Priya explained to PhysOrg.com. “We have recently reported improvements in the piezoelectric ceramic material to enhance the energy harvesting efficiency. As the material and transducer structure continues to improve, piezoelectrics will become more promising. Piezoelectrics are a high voltage-low current source, while electromagnetics are a low voltage-high current source. So in our next generation system, we are designing a combinatory system which will provide better power density.”

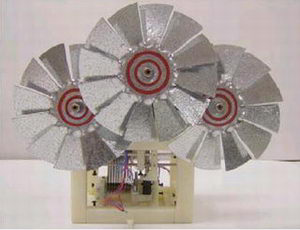

The scientists’ most promising design so far involves three 5-in. (13-cm.) fans mounted on a single shaft through an adjustable gear ratio. Attached to the shaft, a crank arm pulls a lever that is attached to two rows of nine bimorphs. The lever causes the bimorphs to vibrate, converting random wind flow into synchronous mechanical motion. The entire generator size, which is 3.5x4x5.5 in.3, is made of acrylonitrile butadiene styrene (ABS) plastic.

At an average wind speed of 10 mph, the windmill can generate 5 mW of continuous power at a rate of 12 volts. Although a fairly small amount of energy, the windmill can still power sensors, switches, alarms, and wirelessly transmit data, which would be especially useful in remote locations. Further, the generated power can be stored in a supercapacitor for delayed use, and minimally works at wind speeds as low as 5.4 mph.

“Our results have shown that at a wind speed of 10 mph, the accumulated energy in a 0.1F capacitor shows output power levels around 130 mW with current around 35 mA across the 100W resistive load,” Priya said. “The saturation voltage for the capacitor was around 5.5~6V. After 30 minutes, the capacitor was almost charged and saturated.”

The group plans to use their current models as guidelines for designing more efficient prototypes, including the piezoelectric-electromagnetic hybrid. The scientists predict that small-scale windmills can supply energy for powering weather stations, lighting inside tunnels, and monitoring national borders.

“We have recently implemented a wind-powered wireless sensor network using this system,” said Priya. “We are currently working on a design which will enhance the power density by one order of magnitude. The challenge is in capturing the mechanical energy from wind effectively.”

Citation: Myers, Robert, Vickers, Mike, Kim, Hyeoungwoo, and Priya, Shashank. “Small scale windmill.” Applied Physics Letters 90, 054106 (2007).

By Lisa Zyga, Copyright 2007 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.