Electronic components integrated into textile-reinforced composites

Textile-reinforced composites have a high strength at low weight. Therefore, they are interesting particularly for applications in light weight construction and vehicle engineering.

The Fraunhofer IPMS and the Technical University of Dresden cooperate in a partial project of the Collaborative Research Center SFB 639, whose aim is the integration of sensor networks for measuring physical values into a textile-reinforced composite made of glass fibers and polypropylene.

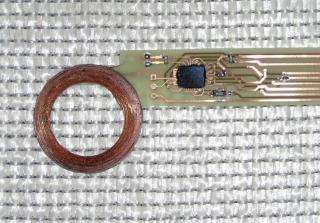

The probability of a damage in the composite, which is not visible externally, could be determined by monitoring of acceleration or strain in a component and a subsequent analysis of the stored characteristic values. Manipulation protected overload monitoring of frame constructions and recording of impacts on containers for sensitive goods are further possible applications for the integrated sensor network. An application specific integrated circuit developed at the Fraunhofer IPMS is used for interfacing the sensors. This ASIC comprises analog interfaces for different sensor types, a digital bus interface and a micro controller with RAM and EEPROM for storing the measured values. A wireless transmission of the stored measurements is enabled by a transponder which is part of the integrated sensor network. It is based on a transponder ASIC which has also been developed at the Fraunhofer IPMS. The integration of the electronics and the curing of the composite is done at high temperature and high pressure. Therefore, high thermal resistance and pressure stability are required for all components.

For demonstrating the function single components of the sensor network were assembled as modules on flexible printed circuit boards and integrated into plates. The demonstrator for strain measuring comprises a plate with integrated sensor ASIC and strain gauge, which can be bent by a loading device. The second demonstrator shows the data transmission between a PC and the transponder integrated into a plate made of textile-reinforced composite.

A demonstration will be shown at the electronica show 2006 in Munich, Germany (14th to 17th November 2006).

Source: Fraunhofer IPMS