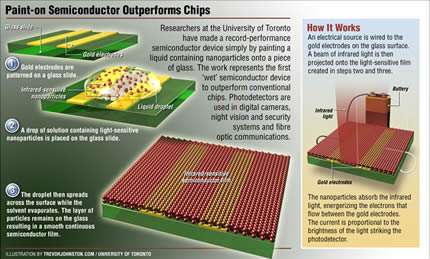

Paint-on semiconductor outperforms chips

Researchers at the University of Toronto have created a semiconductor device that outperforms today's conventional chips -- and they made it simply by painting a liquid onto a piece of glass. The finding, which represents the first time a so-called "wet" semiconductor device has bested traditional, more costly grown-crystal semiconductor devices, is reported in the July 13 issue of the journal Nature.

"Traditional ways of making computer chips, fibre-optic lasers, digital camera image sensors – the building blocks of the information age – are costly in time, money, and energy," says Professor Ted Sargent of the Edward S. Rogers Sr. Department of Electrical and Computer Engineering and leader of the research group. Conventional semiconductors have produced spectacular results -- the personal computer, the Internet, digital photography -- but they rely on growing atomically-perfect crystals at 1,000 degrees Celsius and above, he explains.

The Toronto team instead cooked up semiconductor particles in a flask containing extra-pure oleic acid, the main ingredient in olive oil. The particles are just a few nanometres (one billionth of a metre) across. The team then placed a drop of solution on a glass slide patterned with gold electrodes and forced the drop to spread out into a smooth, continuous semiconductor film using a process called spin-coating. They then gave their film a two-hour bath in methanol. Once the solvent evaporated, it left an 800 nanometre-thick layer of the light-sensitive nanoparticles.

At room temperature, the paint-on photodetectors were about ten times more sensitive to infrared rays than the sensors that are currently used in military night-vision and biomedical imaging. "These are exquisitely sensitive detectors of light," says Sargent, who holds a Canada Research Chair in Nanotechnology. "It's now clear that solution-processed electronics can combine outstanding performance with low cost."

The U of T development could be of critical importance to both research and industry, according to John D. Joannopoulos, a Professor at MIT. "The ability to realize low-cost, paintable, high-performance designer semiconductors for use as short-wavelength infrared detectors and emitters is of enormous value for a wide range of communications, imaging and monitoring applications," says Joannopoulos, the Francis Wright Davis Professor of Physics and director of the Institute for Soldier Nanotechnologies at the Massachusetts Institute of Technology.

"The key to our success was controlled engineering at the nanometre lengthscale: tailoring colloidal nanocrystal size and surfaces to achieve exceptional device performance," says lead author Gerasimos Konstantatos, a doctoral researcher at UofT. "With this finding, we now know that simple, convenient, low-cost wet chemistry can produce devices with performance that is superior compared to that of conventional grown-crystal devices."

Source: University of Toronto