Soft Materials Buckle Up for Measurement

Buckling under pressure can be a good thing, say materials scientists at the National Institute of Standards and Technology. Writing in the June 13 issue of Macromolecules, they report a new method to evaluate the mechanical properties of soft polymers and gels, such as those used in contact lenses and as tissue-engineering scaffolds. For such applications, stiffness is an indicator for key material performance qualities, such as comfort and durability, and it is important to controlling cell adhesion.

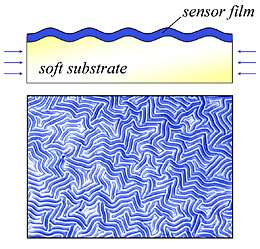

The new method uses “sensor films” with known properties to report the stiffness (or “modulus”) of the soft substrates to which they are attached. Compressing the sample causes the sensor film to buckle, resulting in patterns of repeating ridge-like features, akin to corrugated cardboard. The ridge spacing is related to the modulus ratio between the film and the soft substrate. Since the mechanical properties of the sensor film was known, the researchers could calculate the stiffness of the soft material underneath.

In the journal article, the team focuses on results achieved with model soft specimens, such as silicone polymer, and more challenging “hydrogel” specimens (networks of polymers swollen with water). In each case, the researchers tested “gradient” specimens that changed in their mechanical properties across the lengths of a sample. With the sensor film, they could track and measure changes in stiffness in the underlying materials.

This capability makes it possible to “map” spatial variations in rigidity in complex materials and devices. Accordingly, the new method may be a powerful tool to test for flaws or weak regions in soft materials products, the researchers suggest.

Another key aspect of the technique is its speed. The NIST team is working with industrial partners to harness this method as a high-throughput measurement tool for rapidly testing large numbers of soft polymer products. For more information on this aspect of the research, see the NIST Combinatorial Methods Center Web site.

Citation: E.A. Wilder, S. Guo, S. Lin-Gibson, M.J. Fasolka, and C.M. Stafford. Measuring the modulus of soft polymer networks via a buckling-based metrology. Macromolecules. 2006, 39, 4138-4143.

Source: NIST