Making the biofuels process safer for microbes

A team of investigators at the University of Wisconsin-Madison and Michigan State University have created a process for making the work environment less toxic—literally—for the organisms that do the heavy lifting in the increasingly important field of bioproducts derived from cellulosic biomass.

When industrious bacteria like Saccharomyces cerevisiae, Zymomonas mobilis and Escherichia coli go to work converting the sugar in corn stover and other plant-derived materials into ethanol, they also run into aromatic compounds, which, for these particular organisms, are toxic. This slows down the conversion process—a big problem in a field that needs to economize as much as possible to compete with fossil fuels.

"There's about a billion tons of that biomass material that the U.S. could produce in a year, separate from food production," says Daniel Noguera, the Wisconsin Distinguished Professor of civil and environmental engineering at the University of Wisconsin-Madison. "If that material could be converted to just glucose, that would be perfect, but there are other materials that are part of the plants."

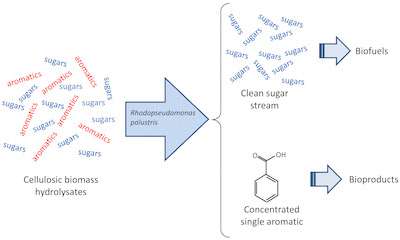

Noguera, along with a team of chemists, microbiologists and engineers associated with the Department of Energy Office of Science-funded Great Lakes Bioenergy Research Center and Wisconsin Energy Institute at UW-Madison, proposes sending in a sort of microbial cleanup crew to make things safer for the glucose-eaters. The plan relies on Rhodopseudomonas palustris, a metabolically versatile bacterium that feeds on the aromatics, but isn't interested in the sugars. This offers an advantage over currently available chemical processes for removing the aromatics, which also remove some of the glucose, which means less valuable fuels or chemicals in the end.

This advance comes as the bioproducts world increasingly seeks to take advantage of the inedible parts of plants, assuaging an imbalance between the world's fuel and food needs. In 2014, the United States bioproducts industry opened its first-ever processing plants that derive ethanol from cellulosic biomass including corn stover, the leaves and stock of corn plants.

The industry is also facing up to the fact that "bio-refineries" must offer a whole slate of products, not just fuels, to compete with diverse fossil-fuel operations, and R. palustris could help with that as well. By manipulating the organism's metabolic pathways, engineers could derive other useful by-products. For instance, R. palustris can convert that complex brew of aromatic compounds into different acids that serve as important precursors for many products in the chemical industry.

"From 30 or 40 different aromatics, we can either remove most of them or concentrate all those into one or two different chemicals, which you could potentially recover and sell or upgrade to different things," Noguera says.

Given the multidisciplinary, big-picture approach of the GLBRC and WEI, the researchers are continuing research to make sure that this step makes the biofuel and bioproducts production process more efficient as a whole. Such research could also contribute to a more complete understanding of all the chemistry at work in the chemical soup that results when plant matter is broken down in this process, and of ways to genetically manipulate the metabolism of the organisms involved.

"Now that we have identified an organism that consumes the aromatics without consuming the sugars, we would like to optimize it," Noguera says. "Part of that is to make it able to consume more of the aromatics, to make it more resilient to the concentration of other materials that might be there, and to make it useful for the many different approaches in which plant material is processed in biorefineries."

The research appeared online on June 29, 2015 in the journal Environmental Science and Technology, and is included in a patent application filed by the Wisconsin Alumni Research Foundation (WARF) directed to microbial methods of removing, transforming, concentrating, and/or converting aromatic compounds from cellulosic biomass hydrolysates. Noguera thinks this research opens up a promising opportunity for the relatively young field of cellulosic biofuels and chemicals production.

"Although using cellulosic biomass is better than using corn for ethanol, this technology is still in its early stages, and we still have many opportunities to improve the engineering and the economics of the process," Noguera says.

More information: "Metabolism of multiple aromatic compounds in corn stover hydrolysate by Rhodopseudomonas palustris." Environ. Sci. Technol., Just Accepted Manuscript DOI: 10.1021/acs.est.5b02062

Journal information: Environmental Science and Technology

Provided by University of Wisconsin-Madison