May 27, 2014 feature

Google Glass and Apple iWatch inspire carbon nanotube fiber batteries

(Phys.org) —If the recently released Google Glass and soon-to-be-available Apple iWatch are any indication, wearable electronics may be the next big wave of the future. Although they offer some cutting-edge features, from head displays to biomedical monitoring, arguably the biggest bottleneck for wearable technologies is the battery. Not only must the batteries be very small and lightweight, but they also have to be powerful enough to meet the energy needs of the devices' many features.

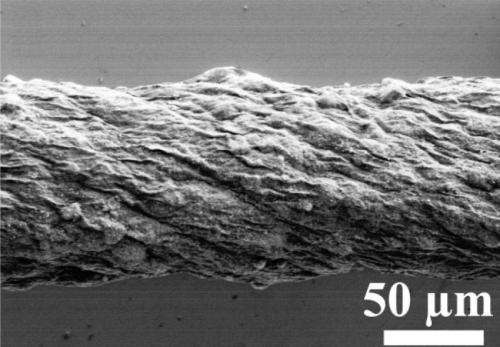

In a new study published in Nano Letters, researchers Wei Weng, et al., at Fudan University in Shanghai, China, have tackled the power problem by designing and fabricating carbon nanotube (CNT) composite yarns that are wound onto a cotton fiber to create a high-performance Li-ion battery. The fibers, which have a diameter of about 1 mm, can then be woven into flexible textile, or cloth, and easily incorporated into flexible wearable electronics.

"A power source that can be directly and seamlessly integrated with the wearable electronics is highly needed," Weng told Phys.org. "Therefore, a power source in a fiber shape is desired because it is flexible and easily woven into a textile. We fabricated a fiber full Li-ion battery based on carbon nanotube fibers for the first time, and the fiber battery can be easily woven into an energy textile with a high performance."

Even though this is the first realization of this CNT fiber Li-ion battery, it exhibits very good electrochemical properties, including a high energy density (0.75 mWh/cm) and the ability to retain 87% of its capacity after 100 cycles.

One of the biggest challenges in designing Li-ion battery fibers is dealing with the widely known silicon expansion problem. During the chemical reactions that occur during the charge/discharge process, silicon undergoes a large volume change of up to 300%. To accommodate the silicon volume change, the researchers incorporated CNTs to make a composite CNT/silicon yarn anode. The CNTs effectively buffer the volume change of the silicon and clamp the silicon down in place. Without this hybrid structure, the silicon's expansion causes it to peel off, damaging the battery.

For the cathode, the researchers used CNTs and lithium manganite, which has benefits including high stability, high working voltage, and low cost. By winding the CNT-based anode and cathode yarns—separated by a gel electrolyte—onto a cotton fiber to make a Li-ion battery, and then weaving the Li-ion batteries into a flexible textile, the researchers demonstrated the feasibility of fabricating a CNT fiber Li-ion battery.

Previously, attempts have been made to fabricate supercapacitor fibers, but not much attention has been given to Li-ion battery fibers due to their difficult fabrication. However, Li-ion batteries have certain advantages, such as higher energy densities and lower self-discharge losses, compared to supercapacitors, so they provide the better option for wearable electronics in general. As Weng explains, the current work improves upon previous research in this area, but still has room for further improvement.

"A Li-ion battery with a similar shape (cable-type) was reported in 2012 using copper wire as a skeleton," he said. "The result is wonderful but maybe not suitable to be woven into an energy textile. The battery has a large diameter, uses liquid electrolyte and is heavy. Here, we use carbon nanotube fiber as the skeleton whose density is nearly 1/9 of the copper, and we use gel electrolyte to guarantee the safety. Also the composite yarn anode and cathode made of carbon nanotube fiber and active materials present a small diameter of 100 µm which is just 1/10 of the anode in the cable battery. Therefore, our fiber battery is compatible with polymer fibers which are used to make clothes and also achieved a high performance."

In the future, the researchers plan to further improve the fiber batteries in a variety of areas.

"Firstly, we want to improve the performance, such as capacity and cycle life," Weng said. "Secondly, we want large-scale production. Thirdly, other functions will be combined, e.g., stretchable, allochroic [color-changing], and self-powered."

More information: Wei Weng, et al. "Winding Aligned Carbon Nanotube Composite Yarns into Coaxial Fiber Full Batteries with High Performances." Nano Letters. DOI: 10.1021/nl5009647

Journal information: Nano Letters

© 2014 Phys.org