October 9, 2013 feature

Future phones and laptops could have speakers made of carbon nanotubes

(Phys.org) —For the past year, researchers at Tsinghua University in Beijing have been listening to music on a laptop through a pair of unusual earphones. Although the earphones look ordinary, they do not contain the typical metal coil speaker found in most earphones, but rather a chip made of many string-like carbon nanotube (CNT) yarns with grooves etched in them. Because they are easy to fabricate, operate on 60 mW of power, and provide clear sound quality, the CNT-based chips could be used as components in a wide variety of speakers, including those found in cell phones and laptops.

"The CNT thermoacoustic chip is silicon-based, vibration-free, thin, and magnetic-free," Yang Wei of Tsinghua University told Phys.org. "It introduces CNT-based nanotechnology into the conventional semiconductor industry. This breakthrough will greatly lower the cost and thus promote the commercialization of nanotechnology. More functionalized devices can be integrated into the thermoacoustic chip, as it is based on a silicon wafer. The CNT speaker can work for a long time thanks to its vibration-free characteristic. The small thickness allows it to meet the demand of device miniaturization. The disadvantage is the low efficiency, as indicated by the sensitivity. But the power consumption of the CNT earphone is acceptable for consumer electronics."

In their paper published in a recent issue of Nano Letters, the researchers explain that the CNT speakers operate completely differently than conventional speakers. Most loudspeakers produce sounds by the mechanical vibration of a physical material, such as metal, paper, or plastic, which then causes surrounding air particles to vibrate. In contrast, the CNT speakers produce sounds due to an alternating current that periodically heats the CNT yarn array, which creates temperature waves in the surrounding air. The thermal expansion and contraction of the surrounding air generates sound. Despite the differences between these two methods of sound production, the sound from the CNT speakers is essentially the same as that generated by mechanical vibration.

Thermoacoustic effects were known about as far back as 1917, when physicists H.D. Arnold and I.B. Crandall, working at the Research Laboratory of the American Telephone and Telegraph Co. and Western Electric Company, Inc., which later became Bell Labs, observed that feeding an electric current into a thin conductor could produce sounds and act as a thermophone.

However, there was no significant progress on thermoacoustic effects until 2008, when a team of researchers from China, including some of the authors of the current paper, fabricated a thermoacoustic loudspeaker made of a piece of aligned CNT film. The researchers found that using the CNT material in place of a conventional conductor can greatly amplify the thermoacoustic effect due to the CNT film's ultrasmall heat capacity per unit area. In this way, the nanoscale properties of CNT films have made the old thermophone concept practical.

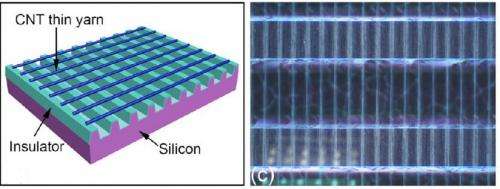

In the current paper, the physicists replaced the aligned multiwalled CNT film with multiwalled CNT thin yarn arrays, which have a high mechanical strength and fast thermal response similar to the film. The CNT yarn arrays were suspended across a series of grooves that were patterned on a silicon wafer, and silver electrodes were pasted on the sides of each chip. The scientists found that the sound pressure level is highly dependent on the groove depth, which here ranged from 5 to 200 um, with deeper grooves providing higher sound pressure levels.

The researchers also determined that, according to temperature wave theory, a substrate or other object that is within one thermal wavelength of the array could possibly cause heat loss and suppress the sound. But as long as the substrate is at least one thermal wavelength away from the array, it does not interfere with sound production.

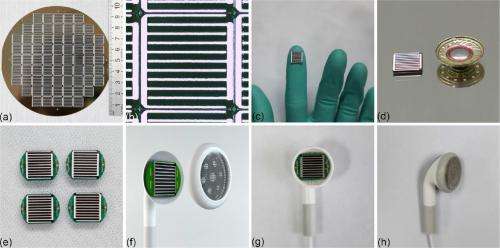

The size of each thermoacoustic chip is 9.5 mm x 9.5 mm, about the size of a fingernail. A single chip can replace the conventional coil speaker in an earphone, with the thermoacoustic chip having the advantage of being much thinner than the coil. Conventional earphone casing usually has small holes on the backside to release pressure generated by the vibrating coil. However, these holes are unnecessary for the thermoacoustic earphone, since there is no vibrational component, and the researchers found that sealing these holes decreases sound leakage, especially at low frequencies.

The thermoacoustic earphone at this stage has an efficiency of 48 dB/mW, which is not as efficient as a conventional earphone, which has a value of about 100 dB/mW. However, as the physicists mentioned, the power consumption of 60 mW is suitable for practical devices.

The researchers demonstrated that the thermoacoustic chip can be assembled into an integrated circuit and powered by a USB. Since the chip involves a silicon wafer, the scientists could package the chip into standard semiconductor casing, which can be easily assembled into PCB board by soldering. In the future, it may be possible to integrate additional features such as memory devices and music players.

The researchers also demonstrated a 4-inch chip array, consisting of 69 chips on one silicon wafer. Larger thermoacoustic speakers could have different applications, which may include long-range acoustic devices and underwater acoustic communication.

"We have proven that a CNT thermoacoustic chip is suitable to be applied in consumer electronics, but there is still a lot of work to be done to commercialize this technology," Yang Wei said. "We will make efforts to optimize the device design and acoustic design and further reduce the cost. More attention from industry will be helpful for the technology promotion, as there is no specialized IC to drive the thermoacoustic speakers, and the CNT earphone is still incompatible with the conventional audio output."

More information: Yang Wei, et al. "Thermoacoustic Chips with Carbon Nanotube Thin Yarn Arrays." Nano Letters. DOI: 10.1021/nl402408j

Journal information: Nano Letters

© 2013 Phys.org. All rights reserved.