1000 calibration reports . . . and counting

The U.S. Internet – and indeed any communication system that sends information by fiber-optic cable – depends critically on strong, clear signals propagating reliably through transmission lines. The principal measurement for evaluating the performance of those systems and their components is optical fiber power, so the meters used have to be very precisely calibrated.

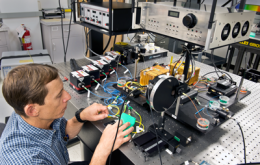

That's where Igor Vayshenker of PML's Quantum Electronics and Photonics Division comes in. An internationally recognized expert on fiber power measurement, he recently completed his 1000th calibration folder for optical power meters.

By any standard, that's an extraordinary record. "Since NIST began tracking calibration customer metrics in 1992," says Marla Dowell, Leader of the Sources and Detectors Group, "Mr. Vayshenker has been personally responsible for the completion of over 2700 calibration tests or one test every business day on average, with a 96 % on-time completion rate, resulting in over $2.7 million in revenue for the federal government. And he has provided critical support to the qualification of optoelectronics and telecommunications equipment, directly impacting every American who makes a long distance phone call or uses the Internet."

The process begins when one of Vayshenker's more than 70 customers, which include national laboratories as well as commercial firms, send their meters to his Boulder lab. There he measures power response over 12 orders of magnitude, from watts down to picowatts, at wavelengths from 633 nm up to 1630 nm, depending on customer requirements. Expanded calibration uncertainty is no greater than 0.5%.

"We compare the customer's optical power meters against our laboratory standard—a pyroelectric radiometer whose design was first developed here in the 1970s – which is traceable to the NIST standard cryogenic radiometer," Vayshenker says.

Calibration proceeds in three stages. First, an optical power meter is tested against specific fixed-wavelength lasers with well-characterized power output (about 100 mW) to get a general idea of performance. Then it moves over to a system of tunable lasers where the meter is exposed to multiple wavelengths and power levels. Meter responsivity can vary appreciably as both variables change, and "we calibrate multiple times on multiple days for each wavelength and power level," Vayshenker says.

The pyroelectric radiometer requires a "chopped" laser beam that is switched on and off at 15 Hz. Photons transfer their energy to the detector as heat, which in turn changes the electrical polarity of the detector material. Results are recorded as electrical signals. Because the devices under test are designed for continuous-wave (CW) use, there are complex electronics to achieve equivalency between CW and pulsed beam.

Finally, the meters to be tested are moved to another set of apparatus that measures linearity of response for three wavelengths (850 nm, 1300 nm, and 1550 nm) up to a few milliwatts, and two wavelengths (980 nm and 1480 nm) for meters that operate at power levels up to 2 watts. Linearity of response of an optical power meter differs with wavelength and the material used in the optical detector, and the analyzed data are presented in tables or graphs.

Discover the latest in science, tech, and space with over 100,000 subscribers who rely on Phys.org for daily insights. Sign up for our free newsletter and get updates on breakthroughs, innovations, and research that matter—daily or weekly.

"It's a very complicated matter," Vayshenker says. "A meter may have a linear response at one power level, but if you go up or down, suddenly the correction factor changes."

In addition, Vayshenker and colleagues often have to examine, clean, or manipulate the connectors on devices under test, which can significantly affect responsivity of an optical power meter. "We check the connectors with optical and digital microscopes, and use special tapes to clean them," Vayshenker says. "Sometimes a little speck a few micrometers wide on the fiber can obliterate the signal."

A final report, including both optical power and linearity data, is about 10 pages long, with the costs of calibration ranging from a few thousand dollars to many thousand dollars depending on the customer's needs.

Vayshenker has been doing this kind of work for nearly 25 years. His accomplishments have been recognized by numerous awards, including the 2007 Allen V. Astin Award and, earlier this year, the Colorado Federal Executive Board's Rocky Mountain Eagle Award for scientific achievement.

"Igor's technical expertise in high quality optical fiber power measurements is sought out by companies around the world," Dowell says. "His calibration services directly support the NIST mission to promote U.S. innovation and industrial competitiveness through critical measurement solutions for both the commercial broadband communication sector and other government agencies that rely on broadband communication technologies."

One is EXFO Inc., a Quebec City-based global communications test and measurement equipment firm with FY11 sales of $270 million. EXFO's Chief Metrologist, Marc Breton, has called Vayshenker a "worldwide reference for fibered power measurements. . . . [His calibrations] were essential for our company and were the basis of our metrology system."

Provided by National Institute of Standards and Technology