Researchers develop first stable bio-oil for transportation use

(PhysOrg.com) -- Researchers at Virginia Tech are using science to control unstable components in biomass to develop stable oils that can be readily upgraded to transportation fuels for the first time. Biomass comprises recently living organisms such as wood or waste products.

Converting woody feedstocks - in this case, poplar and pine wood - to liquid fuels usually produces bio-oil that is unstable and acidic, and which cannot be converted to transportation fuel using traditional processing technologies.

According to Foster Agblevor, associate professor of biological systems engineering in the College of Agriculture and Life Sciences, these bio-oils present further problems. The oils become thicker during storage, resulting in a substance that turns to char when heated. These bio-oils are unusable for fuel after only a few months in storage.

Agblevor and his research team are working to produce stable bio-oils with the potential to be converted to biogasoline. Other researchers include S. Ted Oyama, the Fred W. Bull Professor of Chemical Engineering in the College of Engineering at Virginia Tech; Francine Battaglia, associate professor of mechanical engineering at Virginia Tech; Ronald McClung, research scientist for BASF Inc.; and Michael T. Klein, dean of the College of Engineering at Rutgers University. They have been working on the research for three years.

The team’s work is based on a theory that by looking at the three unstable components of biomass - cellulose, hemicelluloses, and lignin - and controlling them separately can cause the overall product to become more stable. Thus far, the Virginia Tech-led team has developed catalysts that produce stable bio-oils that can be stored for at least one year without significant increases in viscosity. Agblevor believes this is the first stable biosyncrude ever produced.

“We will be able to move from where we are now to making transportation fuels from biomass without doing complicated processes that have been done in the past, and if it’s pursued aggressively, we should see biogasoline on the market soon,” Agblevor said.

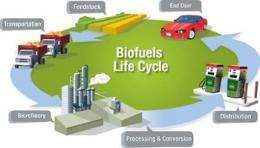

The research overcomes several hurdles by turning biomass into transportation fuels that can directly replace fossil fuels. The research shows a potential pathway toward lowering carbon emissions while using domestic biomass resources to produce sustainable energy for vehicles.

“I think [creating biogasoline in existing refineries] can be done sustainably and cost-effectively within three years if the research in this area is funded,” Agblevor said.

Agblevor is looking at the entire production cycle to understand how the current fuel infrastructure could play a part. “My rationale is that instead of trying to build a new biorefinery that will cost millions of dollars, this process can use existing petroleum refineries and make them green,” he explained.

This new bio-oil could be processed in traditional petroleum refineries, which would leverage existing infrastructure. The next step for Agblevor’s team is to develop a pilot test that will transform biomass materials directly into transportation fuels as evidence that this solution works.

“We are now working on moving forward with developing a demonstration where you’ll see wood coming in one end and, out of the other, we’ll see gasoline,” he said. “This should get everyone very excited.”

Provided by Virginia Polytechnic Institute and State University