May 21, 2010 feature

Paper supercapacitor could power future paper electronics

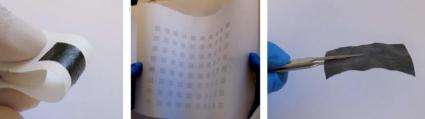

(PhysOrg.com) -- All those paper transistors and paper displays that scientists have been designing can now be powered by an onboard power source, thanks to the development of a new paper supercapacitor. Designed by researchers at Stanford University, the paper supercapacitor is made by simply printing carbon nanotubes onto a treated piece of paper. The researchers hope that the integrated design could lead to the development of low-cost, disposable paper electronics.

In the paper supercapacitor, all the necessary components are integrated onto a single sheet of paper in the form of single walled carbon nanotubes (SWNTs). High-speed printing could be used to print the SWNTs directly onto a piece of paper - anything from Xerox paper to newspaper and even grocery ads will work. At first, the researchers found that the SWNTs were so small that they penetrated the paper through micron-sized pores, which would cause the device to short-circuit. To solve this problem, the researchers first coated both sides of the paper with polyvinylidene fluoride (PVDF), which blocked the pores but still allowed for electrolytes to be transported through the paper. As such, the treated paper could function as an electrolyte membrane and separator without short-circuiting.

“The key design is that SWNTs stick well on paper and do not penetrate through paper completely to avoid shorting,” Yi Cui of Stanford University told PhysOrg.com.

Once the SWNTs were printed onto the treated paper, they experienced strong bonding forces similar to those experienced when writing with a pen or pencil on paper. Even when rubbed or subjected to tape, the SWNTs remained attached to the paper. After printing SWNTs on both sides of single sheets of paper, electrolyte was loaded to form a supercapacitor. The SWNTs served as both the electrodes and current collectors in the supercapacitor, which had a capacitance of about 3 F/g. The device also showed an excellent cycling stability, with very little loss of capacitance after 2500 cycles. The researchers say the same concept could be extended to make batteries, as well.

The fully integrated supercapacitor is based on an earlier version that the researchers made, in which nanomaterials were coated separately onto different anode and cathode substrates and then assembled together with a separator. The advantage of the new integrated structure is that it allows for high-speed printing, which greatly reduces fabrication costs and brings disposable, flexible, and lightweight paper electronics closer to reality. Cui said that, in the future, the researchers plan “to use this new design for real applications.”

More information: Liangbing Hu, Hui Wu, and Yi Cui. “Printed energy storage devices by integration of electrodes and separators into single sheets of paper.” Applied Physics Letters 96, 183502 (2010). Doi:10.1063/1.3425767

Copyright 2010 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.